Machine Monitoring Software

Key Features, Tools and Business Benefits

With 36 years of experience in developing solutions for manufacturing, ScienceSoft offers consultancy and end-to-end implementation of machine monitoring software.

Machine Monitoring System: the Gist

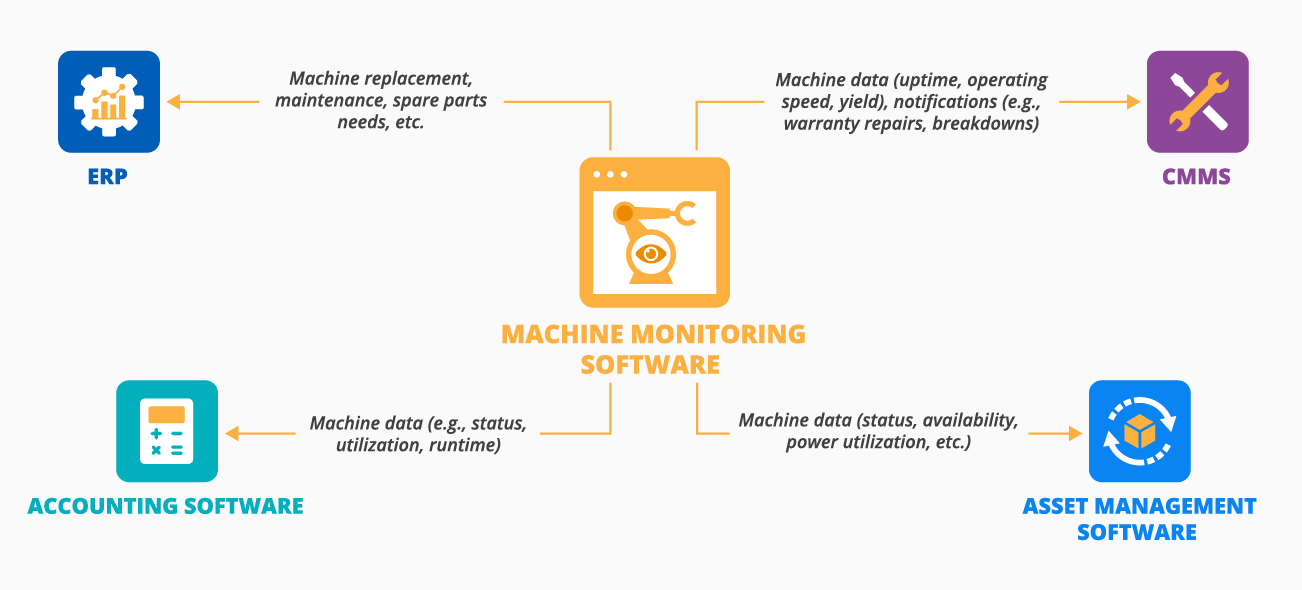

A machine monitoring system provides real-time remote tracking of machine data (e.g., utilization, performance, condition, resource consumption), automated data collection, and AI-based analysis. The software helps optimize machine operating, improve OEE, extend machine life cycle, and more. It integrates with ERP, CMMS, asset management software, energy management software, facility management software, and more. Industries like manufacturing, oil and gas, utilities, life sciences, benefit the most from using a machine monitoring system.

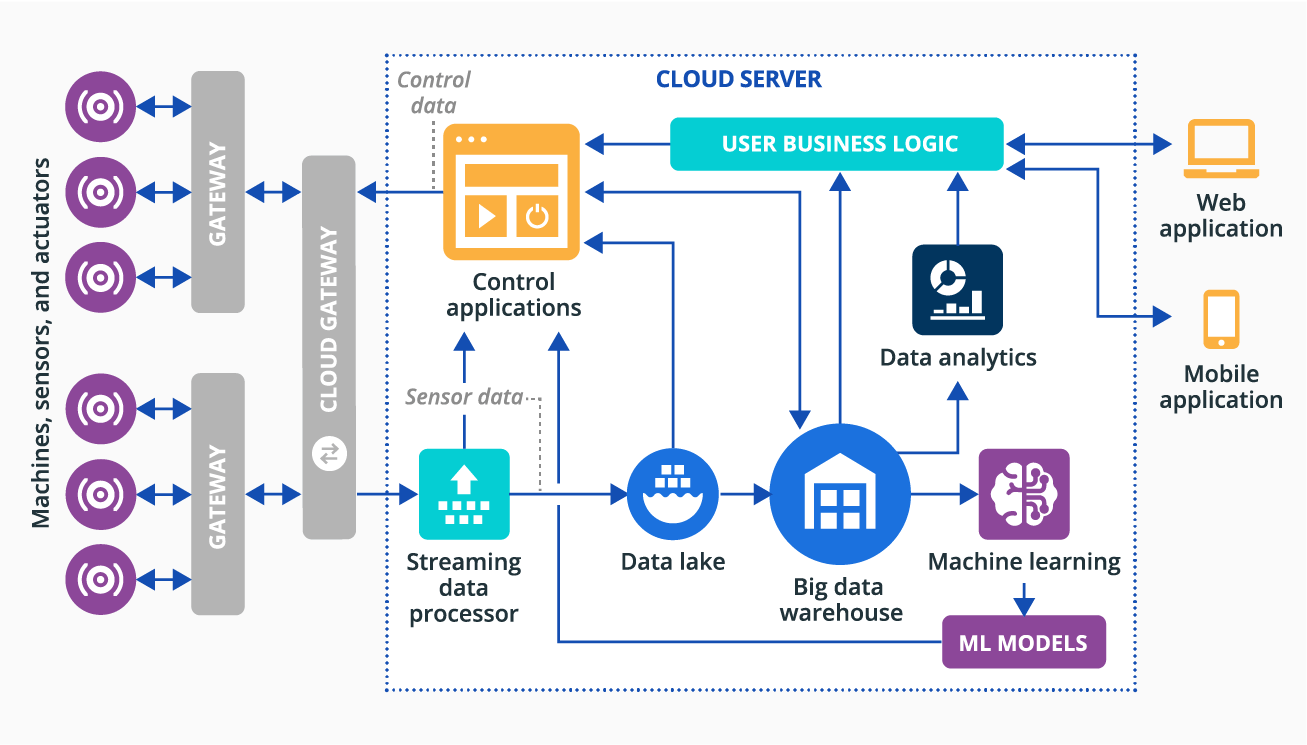

Sample Architecture of a Machine Monitoring Solution

A typical architecture of IoT-based machine monitoring solutions that ScienceSoft builds includes the following components:

- Physical level. Sensors, RFID tags, and GPS tags mounted on machines to collect various data (e.g., temperature, operating speed, location). Collected data goes through the field gateways and the cloud gateway to the streaming data processor. Actuators receive commands from the control apps (e.g., increase or decrease engine rotation speed).

- Data processing level. The streaming data processor transmits the input data to the data lake and control apps. From the data lake where the data is stored in its natural format it gets to the big data warehouse that stores structured data for further analysis. In-depth data analysis helps identify abnormal patterns and trends in machine data and generate actionable insights on how to reduce unplanned downtime, schedule equipment maintenance before failure occurs, and more. The machine learning component creates precise and efficient models based on historical data for control applications that send automatic commands and alerts to actuators.

- Application level. Web and mobile applications enable users (e.g., machine operators, technicians) to communicate with the solution, view real-time machine data and reports, and more based on business logic.

Key Features

Based on ScienceSoft's experience in building machine monitoring software, our consultants made a list of the core features of such solutions.

Machine data monitoring

- Real-time tracking of machine data from IoT sensors, PLCs, and more:

- Status (e.g., on/off, cycle start, setup time).

- Availability (e.g., runtime, downtime, planned/unplanned stops).

- Production (e.g., the number of parts produced, defective parts, reject reasons).

- Condition (e.g., noise, vibration, temperature, pressure, part displacement).

- Resource utilization (e.g., electricity, water, coolants, fuel).

- Operability (e.g., feed rate, cycle time, operating speed).

- A visualized floor plan or a location map with all machinery to show performance compliance or non-compliance with preset values in real time via color-coding.

- Automated routing of notifications about detected issues in machines (e.g., unplanned stops, overheating) via email or text messages to relevant personnel (e.g., an operator, a maintenance worker, a manager).

Document and forms management

- Templates of machine-related documentation (e.g., manuals, daily logs, parts lists, preventive maintenance inspection checklists.

- Search through machine-related documentation.

- Storing document versions with the capability to restore previous versions.

- Built-in form templates (e.g., pre-shift inspection forms, audits) containing such fields as text, checkbox, date, time, numbers, and media (pictures and videos).

- Dynamic form changing based on previously filled out data.

- Multi-user form editing.

- Form e-signing by machine operators and supervisors.

- Form versioning.

- Managing machine-related documents and forms via mobile devices.

Reports and dashboards

- Pre-built report templates (e.g., maintenance history, machine breakdown, compliance reports).

- Customizable role-based reports for machine operators, supervisors, and more on machine availability, condition, performance, etc.

- Real-time dashboards with machine monitoring data (job, changeover, uptime, downtime, cycle time, etc.) and machine KPIs (e.g., availability, utilization, OEE, fully productive time).

- Reports scheduling.

- Analysis of machine data (e.g., yield, machine availability) and identification of abnormal patterns in machine operating.

- Root cause analysis of issues (e.g., malfunctioning, low OEE).

- Physics-based modeling for varying process conditions (e.g., speed, cycle time, pressure) to define optimal conditions for maximized machine operating efficiency.

Forecasting and optimization

- Predicting potential breakdowns and expected time to failure due to corrosion, overheating, load misalignment, and other factors based on machine data analysis.

- Predicting machine behavior (load change, operating problems, etc.) in response to operator actions and working events via creating and testing different scenarios.

- AI-based recommendations for areas of improvement (e.g., mechanical, electrical, pneumatic, software upgrades).

Warranty management

- Tracking the history of warranty repairs for all purchased machines.

- Automated alerts about warranty agreement expiration.

- Identification of warranty repairs for work orders.

- Tracking labor hours spent repairing/replacing items under warranty for warranty claims.

Security and compliance

- Data encryption.

- Multifactor authentication.

- Permission-based access to machine data.

- Audit trail of machine activity (e.g., completed cycles, planned downtimes).

- Data backups.

- Regulatory compliance (e.g., OSHA, FDA, EPA, ISO 9001).

Useful Integrations

ScienceSoft recommends integrating machine monitoring software with other enterprise systems to streamline machine procurement, modernization, maintenance, and disposal.

- ERP - to create full visibility into shop floor data across departments (e.g., Finance, Procurement) for streamlined operational and strategic planning.

- CMMS – to provide accurate data for effective planning and performing of machine maintenance activities (including preventive and predictive maintenance) and automatically create work orders in CMMS when certain issues (manufacturing defects, overheating, etc.) are detected by machine monitoring software.

- Accounting software – to determine machine depreciation costs based on real-time data.

- Asset management software – to schedule machine modernization or disposal based on relevant machine monitoring data.

Success Factors for a Machine Monitoring System

With 36 years in manufacturing IT, ScienceSoft's consultants defined a set of factors, which if covered, help maximize ROI of machine monitoring software.

Mobile user apps and 24/7 notifications

To enable access to machine-related data at any time and using any device and ensure abnormalities will be immediately reported to the relevant personnel via email, SMS, and other channels.

Advanced reporting

To provide full transparency into machine operation, create tailored reports for various user roles (managers, machine operators, maintenance workers), schedule automated report delivery.

Powerful analytics

To get advanced insights about root causes of machine downtimes, rejects, and other issues as well as predict machine failure and provide AI recommendations to optimize machine operating.

Security

Via data encryption, access control, multifactor authentication, and other security measures to protect data on machine health and performance and comply with relevant industry-specific regulations (e.g., OSHA, HACCP, FDA, EPA, ISO 9001).

Costs and ROI

The implementation costs of machine monitoring software vary greatly depending on the number and types of tracked machines, the number of users and their roles, software complexity, required integrations, and other factors.

Curious about costs? Use our cost calculator for a quick, customized estimate designed for your case.

Key financial outcomes

Machine Monitoring Software ScienceSoft Recommends

FourJaw

Best for: Historical trend analysis and benchmarking based on machine data

Description

FourJaw is an intuitive real-time monitoring tool for machines of any type, age or brand that detects and reports production bottlenecks to machine operators or managers.

Features

- Real-time machine monitoring.

- Data visualization.

- Big data analytics.

- Downtime tracking.

- Historical trend analysis.

- Benchmarking.

Pricing

Lite: free

Pro: £59.99 month/machine (annual billing), £79.99 month/machine (monthly billing)

Enterprise: available upon request to a vendor

MachineMetrics

Best for: Predictive maintenance

Description

MachineMetrics is designed for production and machine condition monitoring. It helps create data-driven insights on how to avoid downtime and production losses and increase machine efficiency.

Features

- Real-time monitoring of machine condition.

- Alerts and notifications about detected issues.

- Scheduled reports on machine data.

- Root cause analysis of machine issues.

- Benchmarking.

Pricing

Available upon request to a vendor

Seeq

Best for: Simulation and forecasting

Description

Seeq is an advanced analytics solution for manufacturing data processing to deliver AI-based recommendations on how to optimize machine operations.

Features

- Machine data monitoring.

- Alerts and notifications.

- Reporting.

- Predictive analytics to forecast machine breakdowns.

- Modeling of machine data under various conditions.

- Statistical analysis to define patterns in machine operating.

- Employee collaboration on machine data.

Pricing

Available upon request to a vendor

Raven.ai

Best for: Downtime tracking

Description

Raiven.ai uses proprietary edge devices and advanced AI to capture and analyze production data from machines and operators, which helps reduce OEE losses.

Features

- Identification of downtime causes in real time.

- Real-time guidance for process improvement (e.g., streamline changeover, reduce micro-stops and waiting time).

- Forecasting and historical trend analysis.

Pricing

Core: $199 month/machine

Action: +$30 per module (monthly) or +$100 bundled (monthly)

Premium: +$100 per 5 standard rules, +$50 per additional rule, (monthly)

Connectivity: available upon request to a vendor

When Choose a Custom Machine Monitoring System

ScienceSoft recommends a custom solution when:

|

|

You need a tool that suits your specific production processes while available market solutions don’t. |

|

|

You need to integrate a machine monitoring system with your company’s legacy software (e.g., ERP, CMMS, an asset management system). |

|

|

You want an extra level of data security, for example, AI-powered detection of cyber threats and potentially malicious activities. |

|

|

Your enterprise is bound by specific compliance regulations (e.g., by OSHA, FDA, EPA). |

Machine Monitoring System Implementation with ScienceSoft

In software development for the manufacturing industry since 1989, ScienceSoft offers full-range consulting and implementation services for machine monitoring software.

Machine monitoring system consulting

- Consulting on IoT devices for machine monitoring.

- Defining technical requirements for machine monitoring software.

- Outlining the solution’s architecture and choosing a fitting tech stack (custom implementation) for implementing the solution.

- Consulting on key integrations (e.g., ERP, CMMS, asset management software).

- Elaborating a data security strategy.

- Project planning and a business case creation, including time, cost and ROI estimation.

Machine monitoring system implementation

- Solution requirements engineering.

- Architecture design including an underlying IoT platform and user apps.

- Helping choose, setting and configuring smart devices for machine monitoring.

- UI and UX design of user apps.

- End-to-end solution development including building of user apps.

- Integration of the solution with ERP, CMMS, asset management software, and more.

- Quality assurance of the machine monitoring system.

- Security testing.

- After-launch support and evolution.

About ScienceSoft

ScienceSoft is a global IT consulting and software development company headquartered in McKinney, Texas. We offer advisory, design, implementation, support and evolution services to ensure comprehensive tracking of real-time machine data for manufacturing companies. Being ISO 9001, ISO 27001 and ISO 13485 certified, we guarantee high-quality IT services and the security of our clients’ data. If you are interested in machine monitoring software, reach out to ScienceSoft’s team.