Human-Machine Interface (HMI) Software

Features, Success Factors, Costs

ScienceSoft has been engineering software for the manufacturing industry since 1989.

The Essence of Human-Machine Interface Software

Human-machine interface (HMI) software provides an intuitive graphic user interface with input/output controls to help monitor and operate sophisticated industrial equipment. HMI software can be installed on HMI hardware or regular PCs, mobile devices, and wearables.

Architecture of HMI Software

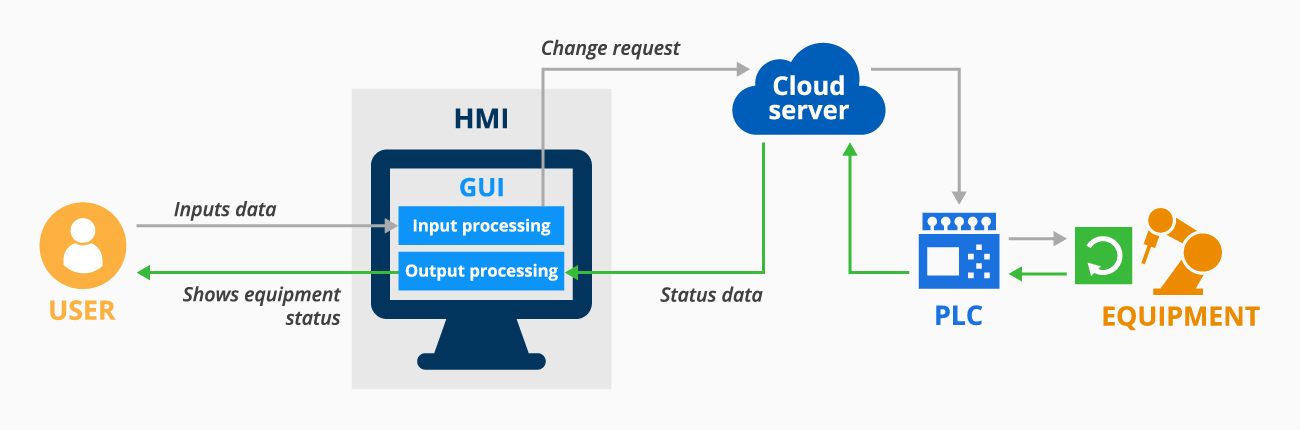

In most cases, HMI software enables the communication between an equipment operator and a Programmable Logic Controller (PLC) in charge of machinery. After receiving a change request from an HMI device, PLC triggers an action in the equipment. Equipment (or sensors/cameras integrated with PLC) communicates status change back to PLC to enable its visualization on HMI.

In most cases, HMI software enables the communication between an equipment operator and a Programmable Logic Controller (PLC) in charge of machinery. After receiving a change request from an HMI device, PLC triggers an action in the equipment. Equipment (or sensors/cameras integrated with PLC) communicates status change back to PLC to enable its visualization on HMI.

HMI solutions used to communicate with PLC via Ethernet cables, but today it makes much more sense to set up HMI-PLC communication via Web APIs located on a cloud server. Integration with cloud enables remote access to HMI software, facilitates data collection, and automates data analytics in the cloud.

Key Features of HMI Software

The HMI features typically requested by ScienceSoft's clients can be united in the following groups:

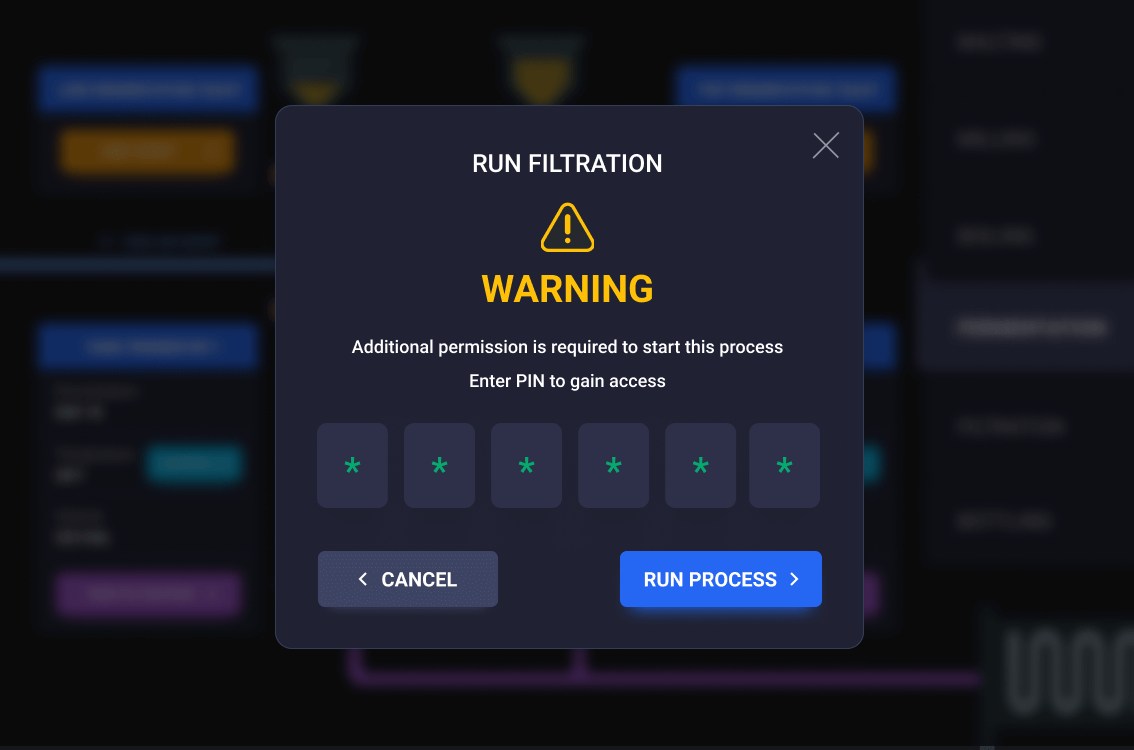

Security

- Role-based access control – users of different roles have different data access permission levels.

- Data viewing restrictions – even if it’s included in monitoring tools and displays with common access, data that requires a higher level of user authorization for viewing will be automatically sanitized and won’t be presented on screen.

Input control

- Data input – triggering changes in machinery behavior via one-off actions.

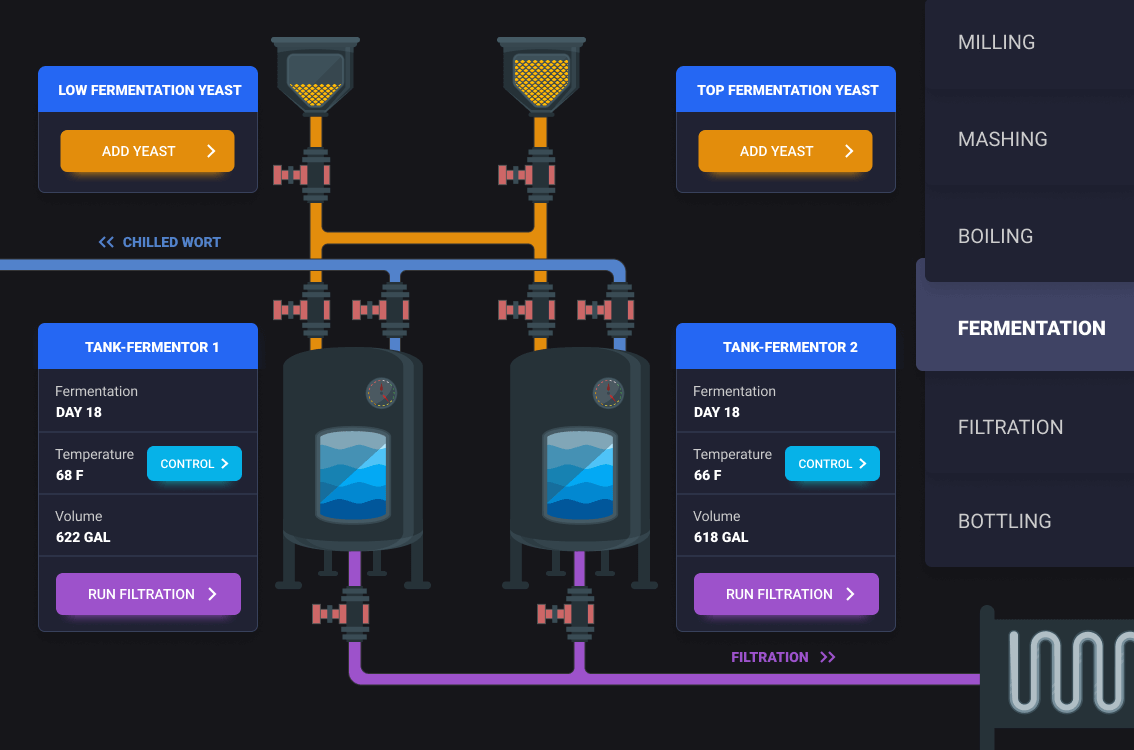

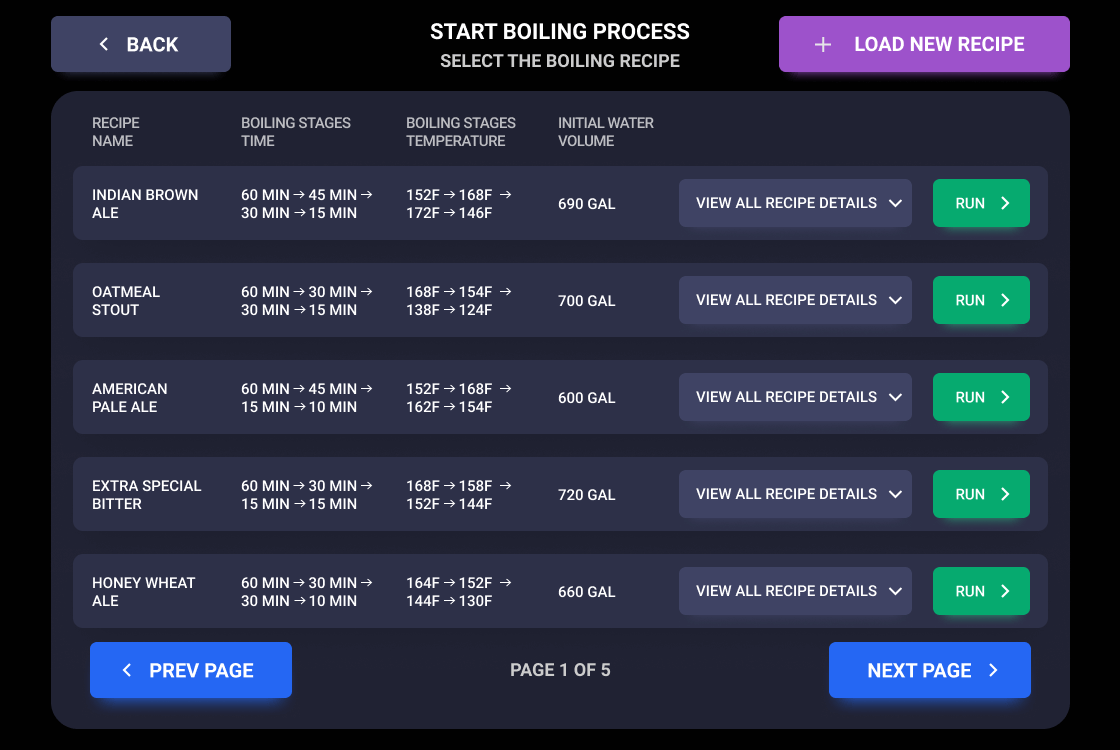

- Data recipes – possibility to trigger a custom set of actions with a single command.

Output monitoring

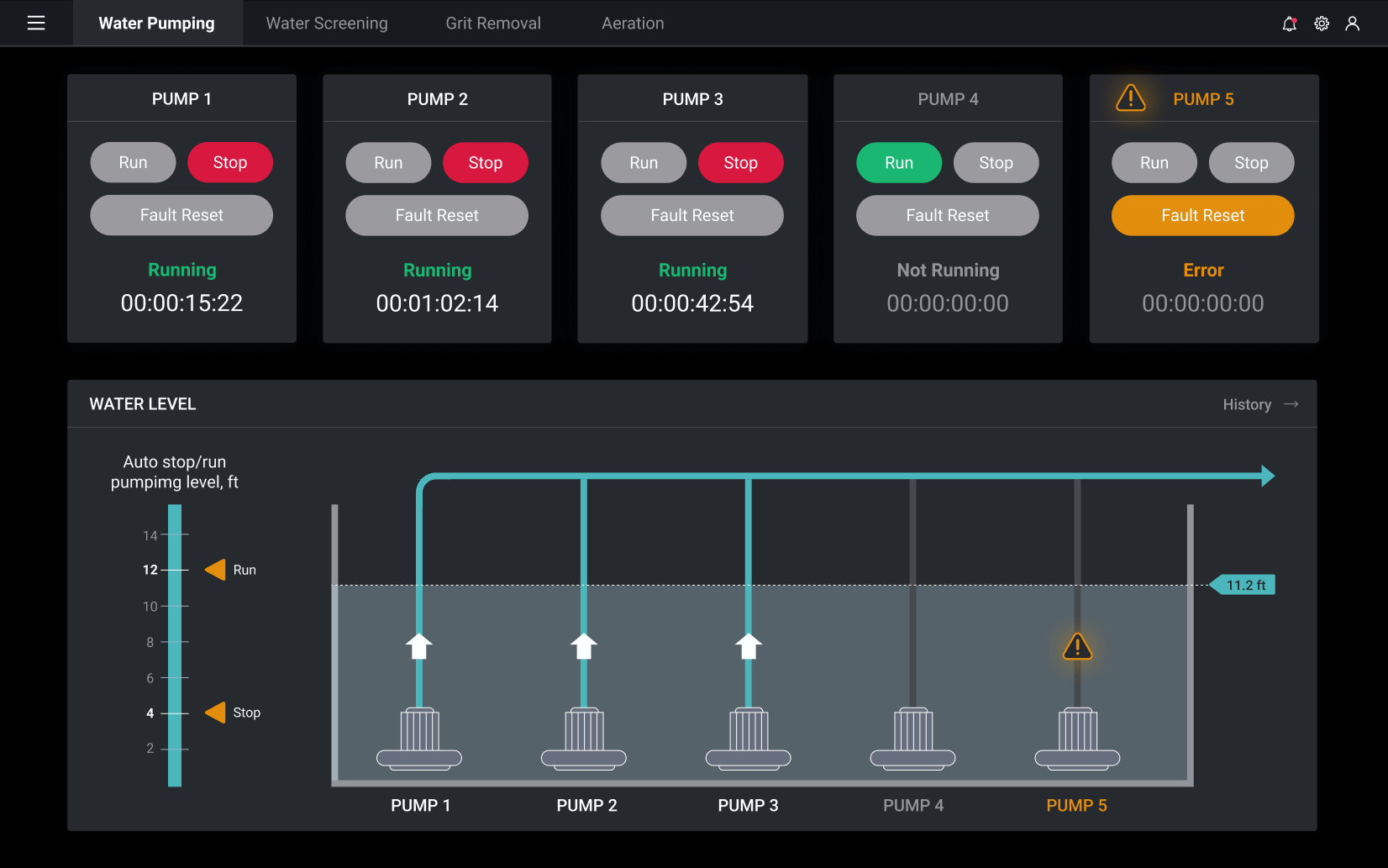

- Process visualization – animated on-screen visualization of an actual workflow in real-time.

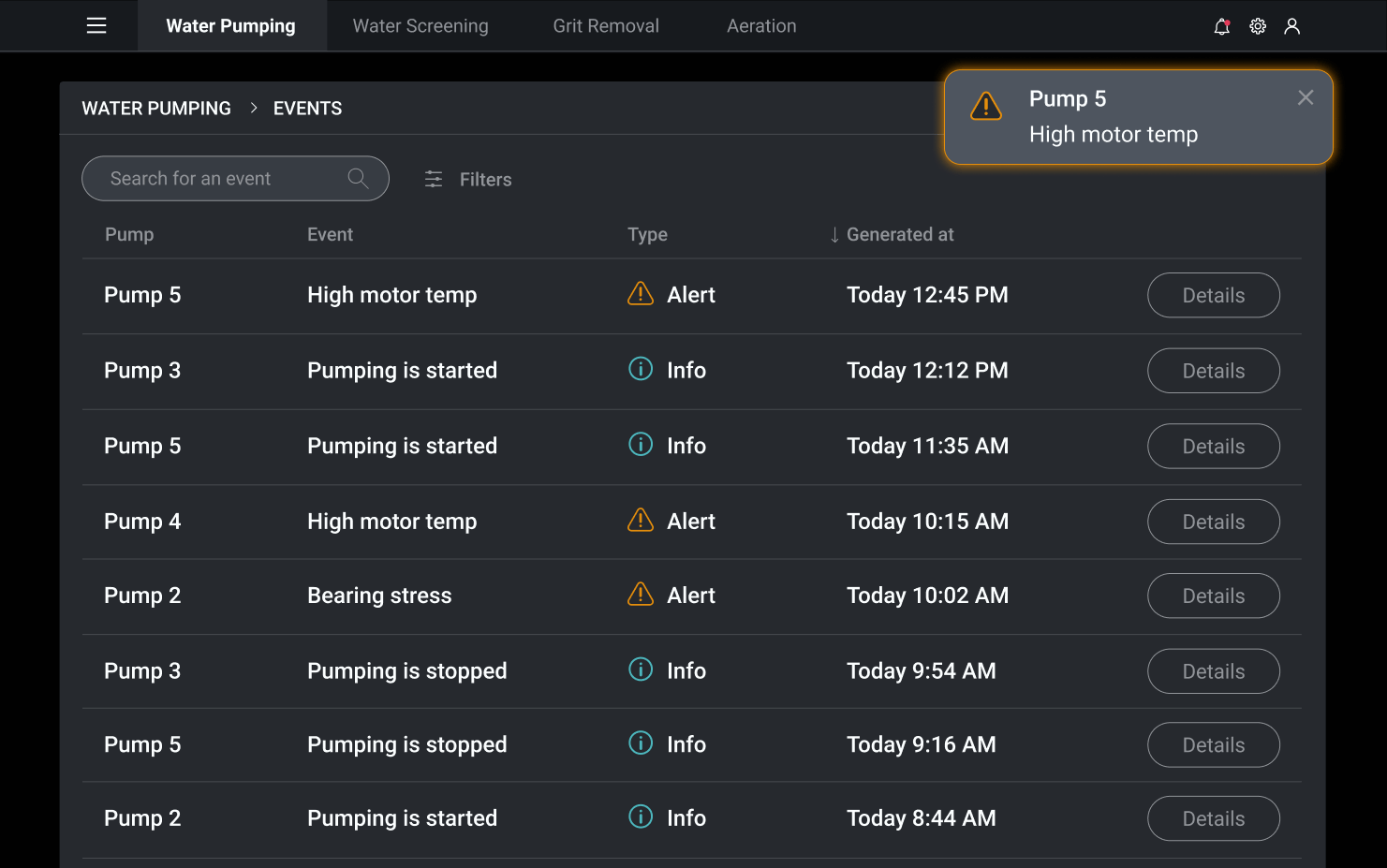

- Automated status change actions – notifications via on-screen messages, sounds, emails, error log entries, etc.

Other

- Dashboard personalization – possibility for machinery operators to choose their necessary tools and organize their own virtual working spaces.

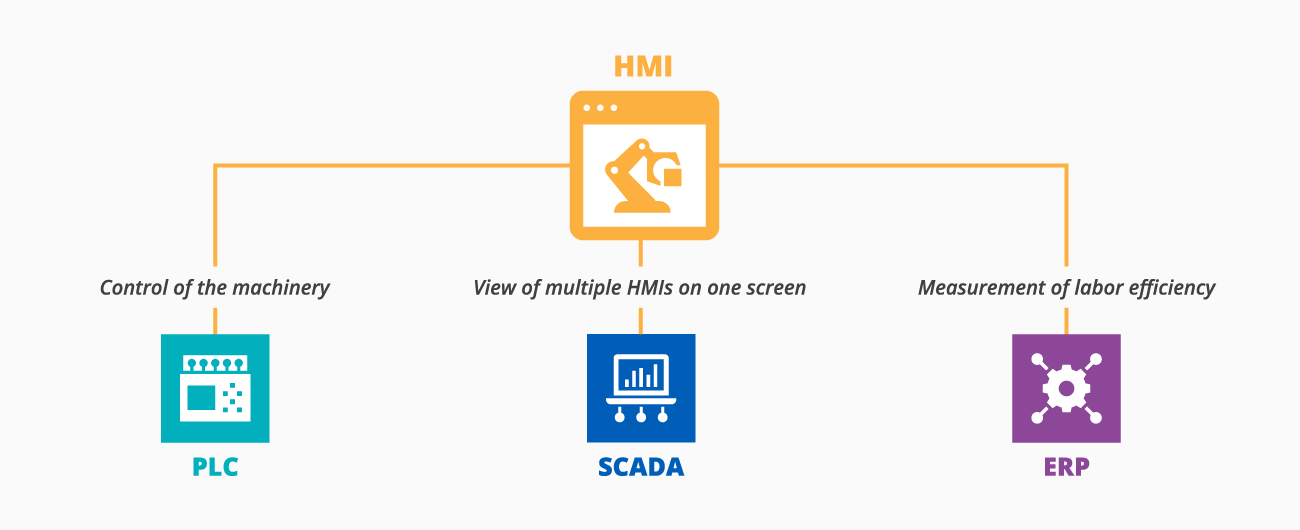

Important HMI Integrations

Since HMI software is mainly an input-output solution, it will only fulfill most of its functions when integrated with other industrial solutions. The most common integration targets in ScienceSoft's HMI projects include:

- PLC - via Web API for mid/large-scale solutions or via Ethernet for small-scale solutions; to enable communication with PLC and thus allow control of the machinery.

- SCADA - to bind multiple HMIs in a network that can be overseen via supervisory software.

- ERP - to allow ERP to regularly receive equipment operators’ activity logs that help measure labor efficiency.

Factors that Determine HMI Success

36 years of experience in the manufacturing industry helped ScienceSoft understand that equipment operators’ work involves high levels of responsibility, stress, and fatigue. That's why we consider compliance of HMI graphic user interface with ISA101 to be the major factor of successful HMI solution. When engineering HMI software, ScienceSoft makes sure that the interfaces are designed to provide high situational awareness and easy situation control, helping to:

|

Focus equipment operators’ attention on top-priority/high-risk processes. |

Make critical issues and errors instantly noticeable. |

Offer intuitive navigation for immediate response to any equipment status change. |

HMI Software Development Costs

From ScienceSoft’s experience, HMI software development may cost from $50,000 to $600,000, depending on solution complexity, the type of equipment to monitor, the scope of required integrations, the number of users and their roles, and more.

Curious about what your project might cost? Use our online calculator to uncover a customized estimate.

Why You Should Consider Custom HMI Software

Off-the-shelf HMI programming software requires from medium to heavy customization to properly reflect your specific industry workflows. In ScienceSoft's experience, this process can pose the following challenges:

- time (and hence, budget) investments that can sometimes exceed custom development costs.

- integration issues caused by combining old and new software/hardware in industrial workflows.

- the need to adapt your needs to the product’s functionality (e.g. abandon the idea of HMI sending alert signals to your operators’ mobile devices if the ready-made product doesn’t allow it).

|

|

With a custom HMI solution developed by ScienceSoft, you:

|

Consider Custom HMI Implementation with ScienceSoft

In manufacturing software development since 1989, ScienceSoft offers both consulting on and implementation of custom HMI software.

HMI implementation consulting

- Analysis of your industrial processes.

- Product vs. custom solution’ SWOT analysis for your individual case.

- Definition of custom HMI’s functional scope.

- Detailed plan of HMI integrations (with PLC, SCADA, ERP, etc.).

- Interactive UX prototype as a PoC.

- Costs and development schedule estimates.

Custom HMI Implementation

- HMI consulting and planning of an implementation project.

- UX design and testing in cooperation with real equipment operators.

- UI design in full compliance with ISA101.

- Development and QA of a custom HMI solution.

- Deployment and integration with PLC, SCADA, ERP, etc.

- Continuous HMI support and maintenance.

About ScienceSoft

ScienceSoft is a global IT consulting and software engineering company headquartered in McKinney, Texas, US. Achieving project goals in spite of time and budget constraints, as well as changing requirements, is ScienceSoft's top priority. You set goals, we drive the project to fulfill them.

Founded with the focus on the manufacturing industry in 1989, we develop custom human-machine interface software to facilitate machinery operation and ensure the safety and effectiveness of industrial workflows. ISO 9001 and ISO 27001 certificates prove our professional approach to quality and data security management.