Overall Equipment Effectiveness Software

Features, Integrations, and Benefits

Drawing on 36 years of experience in creating IT solutions for manufacturing, ScienceSoft offers full-scale consulting and development services to introduce reliable OEE software.

Overall Equipment Effectiveness Software: the Gist

Overall equipment effectiveness (OEE) software tracks and analyzes equipment performance data obtained via equipment sensors or manual input. The tool is used for measuring equipment productivity by unit, shift, facility, etc., and provides valuable insights on how to improve equipment effectiveness and the production process and reduce production losses.

Go-to integrations: ERP, CMMS, asset management system.

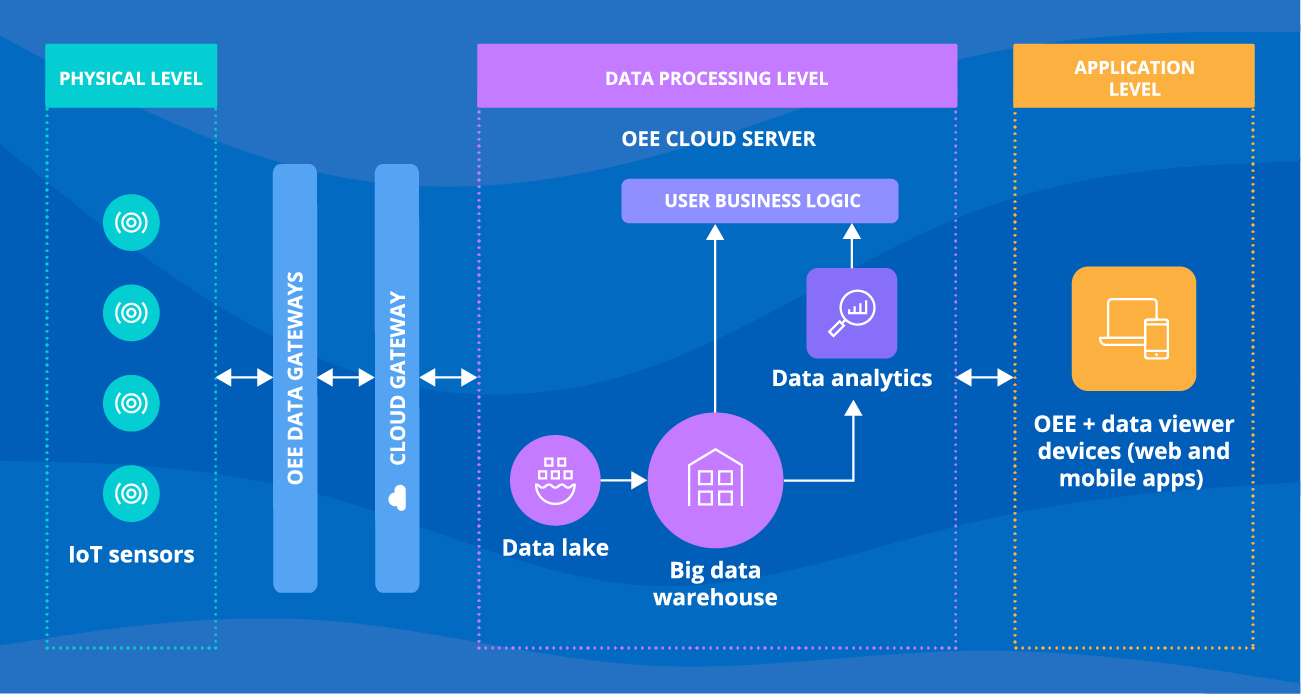

Sample OEE Solution Architecture

We at ScienceSoft suggest our clients to opt for IoT-based overall equipment effectiveness system, which consists of the following components:

- Physical level. Sensors attached to equipment collect data (e.g., line speed, equipment utilization, throughput, yield, cycle time). Collected data goes through the field gateways and the cloud gateway to the streaming data processor.

- Data processing level. The streaming data processor transmits the input data to the data lake and control apps. In the data lake, the data is stored in its natural format, and it gets from there to the big data warehouse that stores structured data for further analysis (e.g., loss analysis, capacity analysis). In-depth comparative data analysis and benchmarking help identify abnormal patterns and trends in equipment data and generate actionable insights on how to optimize OEE.

- Application level. Web and mobile applications enable users (managers, equipment operators) to communicate with the solution, view real-time OEE data in personalized dashboards and reports.

Key Features

Based on ScienceSoft's experience in manufacturing IT projects, we've outlined the core OEE software features that are commonly requested by our clients.

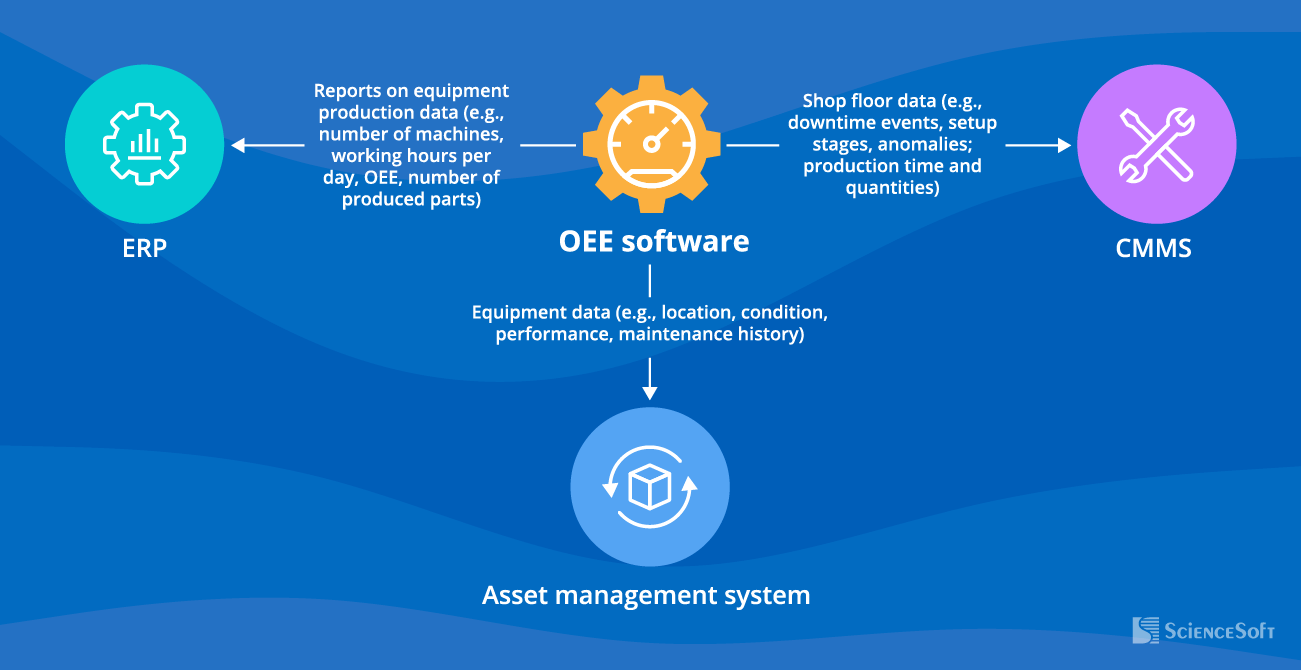

Important Integrations

ScienceSoft recommends integrating OEE software with:

- ERP - to share data from the shop floor with other company departments, increase the accuracy of production cost calculations due to automated data collection from OEE software.

- CMMS – to automatically create maintenance work orders based on shop floor data.

- Asset management system – to streamline equipment planning and scheduling of equipment modernization or disposal.

OEE Software Success Factors

Having ample experience in implementing IT solutions for manufacturing, ScienceSoft consultants defined the key factors, which if covered, help get maximum value from OEE software.

Advanced analytics and reporting

To get accurate OEE score and insights on how to improve equipment performance.

Role-based dashboards

That ensure enhanced accountability to any user role (an operator, a maintenance worker, a manager, etc.).

Intuitive user apps

That enable shop floor workers and managers to easily access floor plans, charts, OEE reports, and other important equipment data without training.

High-level security

Due to encryption, access control, multifactor authentication, and other security measures that protect OEE data and ensure compliance with relevant regulations (e.g., OSHA, EPA).

OEE Software Development Costs

The implementation of overall equipment effectiveness software may cost around $150,000–$600,000+, depending on facility size, the type of equipment to monitor, the number of user roles, the degree of data capture automation (semi-automated or fully automated), feature and integration scope, and more.

Looking for clarity on costs? Use our cost calculator to reveal a tailored estimate for your unique project.

Key Financial Outcomes of OEE Software

Due to efficient real-time monitoring of equipment performance data, downtime root cause analysis, benchmarking, production quality management and equipment maintenance management, OEE software can deliver the following economic benefits:

Equipment Management Products ScienceSoft Recommends

PerformOEE

Description

PerformOEE provides real-time monitoring of equipment performance data for OEE calculation and analysis, OEE trending and benchmarking. The tool can be used across multiple sites within multiple time zones and provide centralized reporting on them. PerformOEE helps increase equipment capacity, reduce production costs and drive continuous improvement of the production process.

Best for

OEE trending and benchmarking

Evocon

Description

Evocon is OEE software that helps manufacturing businesses manage production equipment and improve production efficiency. The tool monitors equipment with hour-by-hour overview of production metrics (e.g., downtime, speed, quality, OEE), visualizes equipment and production data in real time, conducts historical trend and root cause analyses, and more, which helps quickly identify and mitigate production bottlenecks and improve OEE.

Best for

Real-time OEE tracking

XL Platform

Description

XL Platform is designed for real-time equipment monitoring and OEE tracking and creates full visibility into production losses (e.g., run cycle loss, production reject loss). In addition, the tool enables tracking and analysis of labor metrics (e.g., labor efficiency, earned/lost labor, pieces per labor hour) by part, team, shift, etc., which helps identify best labor practices and training opportunities for manufacturing personnel.

Best for

Tracking of production losses and labor metrics

When to Choose a Custom OEE Solution

ScienceSoft’s experts recommend building custom OEE software if you:

|

Have specific manufacturing processes, for example, you need a tool to effectively calculate OEE in bulk, discrete and continuous manufacturing processes. |

Need your OEE solution to easily integrate with other software including custom legacy tools (e.g., ERP, CMMS, asset management software). |

|

Need to calculate custom OEE metrics. |

Must comply with specific internal and external regulations (e.g., OSHA, EPA). |

OEE Solution Implementation by ScienceSoft

Since 1989 in IT for manufacturing, ScienceSoft offers consulting and implementation of OEE software.

OEE software consulting

- Consulting on IoT devices for OEE software.

- Defining technical requirements for the OEE solution.

- Selection of a suitable platform for platform-based implementation or outlining the solution’s architecture and a tech stack for custom development.

- Advising on key integrations for the solution (e.g., ERP, CMMS, asset management software).

- Elaborating on a data security strategy.

- Creation of a project plan and a business case including time, cost and ROI estimation.

OEE software implementation

- Eliciting the OEE solution’s requirements.

- OEE software architecture design.

- Architecture design including an underlying IoT platform and user apps.

- UI and UX design of user apps.

- Development of the solution from scratch or customization of ready-to-go OEE software.

- OEE solution integration with ERP, CMMS, asset management software, and more.

- Quality assurance of the OEE solution.

- After-launch support and evolution.

About ScienceSoft

ScienceSoft is a global IT consulting and software development company headquartered in McKinney, Texas. We offer consulting, design, implementation, support and evolution services to bring robust OEE software that help businesses measure and improve OEE. Being ISO 9001 and ISO 27001 certified, we guarantee high-quality IT services and the security of our clients’ data. If you are interested in OEE software, reach out to ScienceSoft’s team.