Production Scheduling Software

Features, Benefits, Costs, and Tools

In manufacturing IT since 1989, ScienceSoft provides consulting and full-cycle implementation services for production scheduling software that supports lean manufacturing.

Production Scheduling Software: The Gist

Production scheduling software is an essential tool for efficient planning and allocation of resources (e.g., equipment, inventory, human resources) to production processes. It employs AI/ML and IoT technologies to help organizations ensure optimized resources utilization, reduced manufacturing cycle time, and on-time delivery of manufacturing products to customers.

- Users: production managers, sales managers, shop floor workers.

- Go-to integrations: ERP, MES, CRM, accounting software.

- Implementation costs: $50,000–$100,000, depending on the solution complexity. Use our online calculator to find the cost for your case

Key Production Scheduling Software Features

When defining the features for a production scheduling solution, ScienceSoft’s team adjusts them to the specific business needs of a manufacturing organization. Based on our experience in similar projects, we composed a list of the most requested features by our clients.

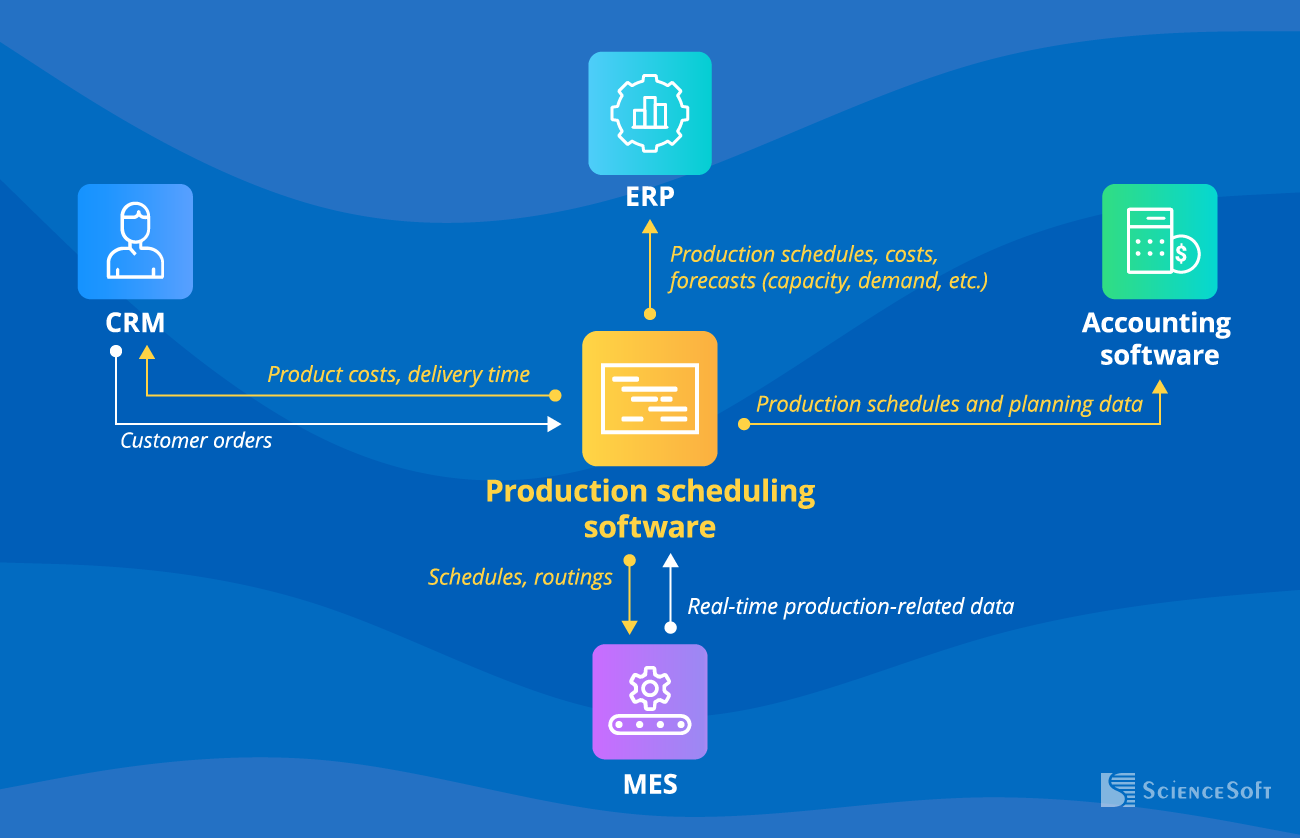

Important Integrations for Production Scheduling Software

- ERP – to streamline future production planning based on the what-if analysis and forecasts provided by production scheduling software.

- MES – to automatically update the schedules in production scheduling software based on the real-time production data collected by MES, and to provide schedules and routings for production processes governed by MES.

- CRM – to create and send quotations and invoices to customers based on product costs and delivery time calculated in production scheduling software; to track the sales process from quotation to product delivery; to launch production processes based on customer orders.

- Accounting software – to provide cash flow forecasts based on production schedules and planning data from production scheduling software.

Success Factors of Production Scheduling Software

With 36 years in manufacturing IT, we’ve gathered the key factors that determine the success of production planning software.

Relevance for specific KPIs, constraints, and business rules

Defining a set of target KPIs (e.g., -15% inventory levels, +30% productivity, 1.5x faster product delivery) will help you prioritize crucial features to see if a certain tool would be able to help you achieve those goals. Also, the chosen software should capture all relevant constraints and business rules in order to define the perfect production schedule.

Advanced optimization capabilities

Powered with advanced techs (AI, ML, IoT), production scheduling software would be able not only monitor and schedule but also significantly optimize production processes by analyzing production data. This, in turn, would help ensure higher ROI since optimization brings much higher cost savings and encourages the lean approach to manufacturing.

Customizability

As your business grows over time, production needs and manufacturing standards also change. Your software should be able to keep up: going for a scalable and customizable solution will help avoid costly software redevelopment in the future.

Smooth integration with business-critical systems

Production scheduling software should smoothly integrate with enterprise systems like ERP, MES, and CRM to ensure interoperability and data consistency across the company’s digital environment, helping achieve efficient business process automation.

How Much Does It Cost to Implement Production Scheduling Software

The cost of production management software can vary greatly depending on the number of locations (single-plant or multi-plant enterprises), the number of active production orders/projects, and required integrations.

From ScienceSoft's experience, implementing custom production scheduling software of moderate complexity may cost around $100,000–$200,000.

Explore the costs specific to your needs—use our cost calculator to get a quick, customized estimate for your case.

Key benefits of production scheduling software

- +20% productivity due to thorough planning of resources (equipment, labor, materials, etc.).

- -50% excess inventory due to synchronizing purchasing with an optimized production schedule.

- -70% downtime due to real-time alerts.

- -90% time spent on forecasting, planning, and ordering due to AI-driven automation.

Off-the-Shelf Production Scheduling Software ScienceSoft Recommends

MaxScheduler

Description

MaxScheduler is an easy-to-use web solution for assigning jobs to available employees and machines. It offers features such as scheduling via drag-and-drop capabilities, graphical schedules for a more visual feel, and user profiles (e.g., Schedulers, Editors, and Viewers) to set permissions.

Best for

Companies in manufacturing, printing, warehousing, logistics.

JobPack

Description

JobPack is an on-premises scheduling solution that can be easily integrated with other enterprise systems. For example, integration with an ERP enables the tool to import sales orders, work orders, and routings from the ERP to create a real-time graphical scheduler for various machinery (e.g., for milling, turning, grinding). JobPack’s planning board allows users to assess potential impact of production schedule adjustments and test multiple scenarios (‘what-if’ scheduling). The tool also enables viewing available capacity and managing operational constraints to avoid operations overlapping.

Best for

Metal cutting and manufacturing companies in aerospace, automotive, and job-shop industries.

PlanetTogether

Description

PlanetTogether streamlines managing orders, capacity, and inventory. It offers such features as production scheduling, constraint management, capacity planning, order management, alerts, reports, and communication tools. PlanetTogether also provides advanced analytics features (e.g., capacity, productivity, financial analytics), which helps improve decision-making and optimize production processes.

Best for

Manufacturing companies with a focus on supply chain management.

When Off-the-Shelf Production Scheduling Software is Not Enough

Developing a fully custom production scheduling solution can be the best option in the following cases:

|

|

The off-the-shelf products lack the features that are critical for the customer. In this case, custom development may be more cost-effective than customization of an already existing product. |

|

|

The customer requires integrations with custom legacy applications (e.g., ERP, MES, CRM). |

|

|

The customer needs functionality based on AI, ML, IoT, and other advanced technologies to be in production scheduling software. |

|

|

The customer wants branded UI for a production scheduling software. |

Choose Professional Services for Production Scheduling Software Implementation

ScienceSoft’s experienced IT consultants and software engineers are ready to assist manufacturing companies in streamlining their production processes.

About ScienceSoft

ScienceSoft is a global IT consulting and software development company headquartered in McKinney, Texas. We offer consulting, implementation, training, and support services for production scheduling software. We help manufacturers gain full visibility into production processes, avoid scheduling errors, and ensure cost-effective production and on-time deliveries. ScienceSoft’s ISO 9001 and ISO 27001 certificates guarantee high-quality services and complete security of our clients’ data. If you need production scheduling software consulting or implementation, reach out to ScienceSoft’s team.