Custom Warehouse Management System

Features, Success Factors, Costs, Benefits

ScienceSoft leverages 13 years of experience in supply chain software development to help businesses digitally transform and optimize their warehouse operations with tailored software.

Warehouse Management System in Brief

A warehouse management system (WMS) includes functionality for automation of inventory receiving and putaway, order picking and packing, shipping management, inventory tracking, warehouse navigation for workers, warehouse labor planning, and more. Custom WMS can help manage warehouse operations of any scale, from a single to multiple warehouses spread across the country or worldwide.

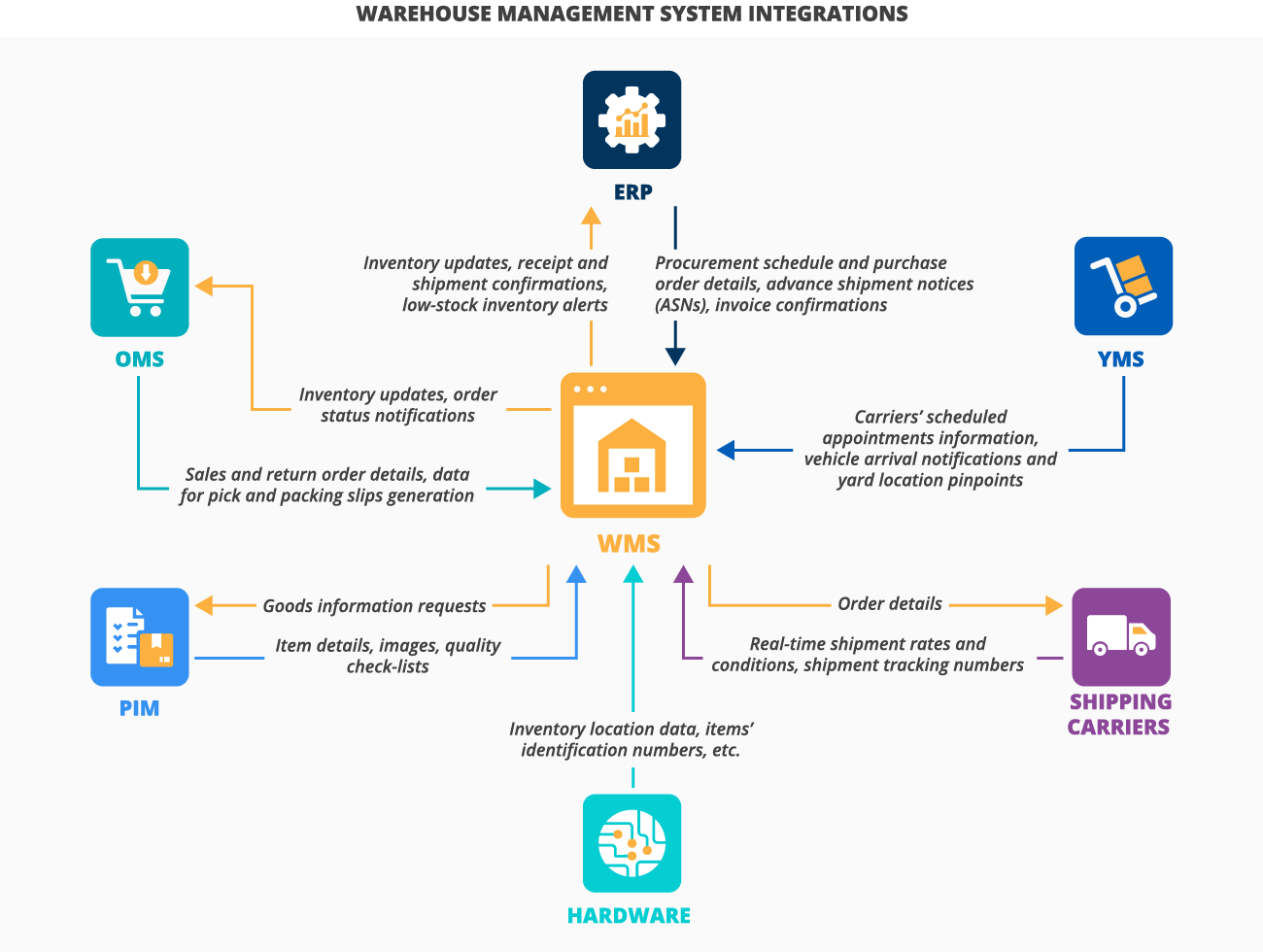

WMS integrates with ERP, order management software, product information management software, shipping carriers’ systems, and more.

Developing a full-scale custom WMS may cost around $200,000–$400,000+, depending on the software complexity. Use our free calculator to estimate the cost for your case.

Key WMS Features

Below, ScienceSoft outlines the fundamental WMS functionality that accommodates the majority of real-life use cases.

Benefits of Custom WMS

Below, our consultants list the major financial gains that compose the ROI for WMS implementation:

|

|

5–40% reduction in stock inventory with no stockout risks due to data-driven inventory planning and optimization. |

|

|

10–20%+ improvement in warehouse space utilization efficiency due to analytics-based inventory placement. |

|

|

10–30% decrease in inventory carrying costs due to optimized inventory storage and eliminated overstocking. |

|

|

50–99%+ savings on inventory shrinkage due to technology-supported stock counting and real-time inventory tracking. |

|

|

25–50% lower fulfillment costs and 99%+ fulfillment accuracy due to intelligent guidance on order picking and packing. |

|

|

10–35% increase in warehouse labor utilization thanks to accurate labor demand forecasting and automated task planning. |

Is Custom WMS the Right Fit for You?

Answer a few simple questions and find out whether you should opt for a custom WMS or a ready-made warehouse tool.

Do you need software to support complex workflows like multi-warehouse management, omnichannel fulfillment, or warehouse robotics control?

Do you need a WMS providing specific features, e.g., inventory auto-replenishment, IoT-based stock counting, or AR-assisted warehouse navigation?

Do you want to leverage AI-supported planning and optimization of inventory, labor, storage space, and warehouse operations?

Do you need to integrate your WMS with multiple corporate solutions, supplier systems, or specific warehouse hardware, including legacy tools?

Do you work with regulated inventory (e.g., drugs, commodities, strategic electronics, military items) and need a WMS that adheres to strict security and compliance requirements?

Do you need a customizable WMS with various interfaces for different roles in the warehouse team (warehouse workers, inventory specialists, analysts, etc.)?

Do you plan to evolve the solution with new functional and non-functional capabilities in order to adjust it to changing business requirements?

Do you have large teams involved in warehouse processes and look to avoid the software fees associated with the per-user pricing model?

Please tell us a bit more about your needs

Answer at least 3 questions to get results.

You can go with off-the-shelf WMS

Looks like market-available warehouse solutions are a viable option to meet your needs. Turn to ScienceSoft if you need help with choosing the optimal ready-made WMS, its implementation, customization, or integration with your existing systems.

You definitely should consider custom development

A tailor-made WMS will help you reap the unique benefits that market-available software cannot offer. Turn to ScienceSoft to get a detailed assessment of a custom WMS feasibility for your business situation.

Custom WMS is your best choice

Looks like market-available warehouse tools don’t fit your specific needs and won’t be able to provide the expected operational and economic feasibility. Turn to ScienceSoft to get a consultation on custom WMS and receive free cost and ROI estimates.

Important Integrations for WMS

ScienceSoft recommends integrating WMS with:

- Enterprise resource planning software – to provide visibility into warehouse operations for all departments involved (accounting, procurement, manufacturing, etc.); for WMS users to be updated on incoming purchase orders issued in ERP and request invoice generation.

- Order management software – to keep customers and sales agents up-to-date on available items (e.g., to minimize the chances of out-of-stock items being ordered). Alternatively, WMS can be integrated directly with sales channels (a company’s website, marketplaces, etc.).

- Product information management software – for warehouse personnel to access item details to identify the items easily and carry out quality checks (e.g., at inventory receipt).

- Yard management software – to coordinate yard and warehouse operations, e.g., to load shipments faster, simplify items’ cross-docking between facilities.

- Shipping carriers’ systems – to track shipments and manage shipping costs.

- Hardware (barcode or RFID readers, robotic shelf loaders or forklifts, etc.) – to

increase labor performance and task execution accuracy and reduce associated labor costs.

ScienceSoft's WMS Services

In supply chain software development since 2012, ScienceSoft knows how to engineer reliable and effective WMS solutions for any industry. We offer consulting and development services to support you at any stage of your WMS initiative, ensuring that project goals are achieved within the intended time and budget.

WMS consulting

- Analyzing your warehouse and order fulfillment processes.

- Interviewing key stakeholders to define short-term and long-term WMS needs.

- Designing the optimal architecture, feature set, and tech stack for your WMS.

- Warehouse hardware consulting.

- Estimating development project costs and time budget, calculating the solution’s expected ROI.

- Outlining a risk management plan.

WMS development

- Eliciting business requirements for WMS.

- WMS architecture design.

- Custom WMS development.

- Integrating WMS with the required software and hardware.

- Testing the system end-to-end (functioning, usability, integrations, etc.).

- (optional) User training.

- Providing after-launch support and WMS maintenance and evolution.

WMS Success Factors: What is Important to Consider

In WMS projects, ScienceSoft always seeks to cover the following important factors that may bring the customer additional value across warehouse management processes:

AI-supported workflow optimization

(automated warehouse routing, task interleaving, prescriptions on inventory storage, picking, packing, etc.) to increase warehouse staff productivity and minimize human errors, such as poor warehouse slotting.

Thought-out UX and UI

including for a mobile version, to reduce user training efforts and ensure smooth software adoption at all levels, from warehouse workers to supervisors and managers, to leverage WMS benefits to the fullest.

WMS flexibility and robust performance

(high throughput, low latency) to accommodate the growing scale and complexity of warehouse operations and efficiently handle seasonal rises in customer demand (we prioritize cloud-based systems due to their on-demand scalability).

WMS Development Steps

Warehouse management software development is a complex process that involves business analysis, solution planning and design, coding, quality assurance, integration, and extensive user training. Implementation of a custom WMS with ScienceSoft covers the following steps:

1

Business needs analysis and eliciting requirements for WMS.

2

Designing the optimal feature set, architecture, and tech stack.

3

Project planning: scope, deliverables, schedule, budget, team composition, etc.

4

Custom WMS development.

5

Running the necessary testing procedures.

6

Warehouse data migration (from spreadsheets or a previously used WMS).

7

Integration with the required systems, including hardware systems.

8

User training.

9

After-launch WMS support and evolution (optional).

Costs of WMS Development

The cost of custom WMS varies greatly from case to case depending on:

- The number of warehouses that should be connected to the system.

- The scope and complexity of functional modules required to cover warehouse needs.

- The number and complexity of integrations (e.g., integration with legacy ERP).

- Complexity of data migration procedures.

Based on ScienceSoft's experience, the cost to develop a custom warehouse management system of average complexity ranges between $200,000 and $400,000.

Want to know the cost of your WMS?

About ScienceSoft

ScienceSoft is a global IT consulting and software development company headquartered in McKinney, Texas. We render WMS consulting and development services to help businesses increase warehouse efficiency and reduce related costs via automation and data-driven optimization of inventory handling and visibility into warehouse operations. Feel free to reach out to us to discuss your WMS needs.