Inventory Management Software Development

A Complete Guide

In supply chain software development since 2012, ScienceSoft designs and engineers reliable, future-ready inventory software solutions tailored to each client's specific needs.

Inventory System Development: Summary

Creating an inventory system is a way for companies to improve the efficiency of their unique inventory management workflows, get full control of inventory levels and movements, optimize inventory-related costs, prevent stock-outs and overstocking.

Key steps to engineer an inventory management system

- Engineer requirements and design an inventory system.

- Plan the project in detail.

- Develop inventory software and run QA.

- Integrate the software with other systems.

- Migrate inventory data.

- Deploy the inventory system.

- Conduct user training.

- Ensure after-launch support.

- Team: A project manager, a business analyst, a solution architect, UI and UX designers, software and QA engineers.

- Time: Around 9–13 months for custom inventory system development.

- Cost: $90,000–$250,000 for inventory software of moderate complexity, $250,000–$400,000+ for a comprehensive inventory system. You are welcome to use our free calculator to estimate the cost for your case.

Having 750+ IT professionals with 7–20 years of experience, ScienceSoft can provide all necessary competencies to engineer inventory software end to end and help companies effectively optimize project time and costs.

Types of Inventory Solutions

Visit ScienceSoft's dedicated pages to learn about the features, costs, important integrations, and financial outcomes of inventory solutions we create:

General-purpose inventory solutions

Industry-specific inventory solutions

Having deep practical knowledge of 30+ industries, ScienceSoft can create inventory software for any business segment. Some examples of industry-specific inventory systems we build are:

How to Create an Inventory Management System in 8 Steps

The duration and approach to the inventory system design and engineering depend on the specifics and scale of inventory operations the solution should cover. Below are described the typical steps we at ScienceSoft take to introduce robust inventory software.

1.

Engineer requirements and design an inventory system

ScienceSoft starts inventory system implementation projects with the following steps:

- Eliciting functional and non-functional requirements for an inventory system, defining user roles, required integrations with other systems (ERP, CRM, WMS, POS, accounting system, etc.) and data migration activities (to move data from currently used spreadsheets or an inventory management solution).

- Deciding on the inventory system type: software-only or hardware-supported (barcode/QR code scanning, RFID, computer vision). Outlining a list of required hardware equipment if needed.

- Designing a high-level architecture of the solution with major components and interactions between them. Prototyping UX and UI.

- Composing an optimal tech stack for inventory system development. To streamline and speed up development, we rely on proven frameworks, low-code platforms, and ready-made components where possible.

We render inventory system design in close collaboration with a customer’s subject matter experts to get an in-depth understanding of their inventory management needs and ensure the service fully covers our client’s unique requirements.

2.

Plan the project in detail

ScienceSoft’s experts strongly believe that precise project planning is the cornerstone of a successful inventory system implementation. At this stage, we cover:

- Outlining the scope of work and its duration, associated risks and the ways to mitigate them.

- Calculating expected TCO and ROI of the inventory system.

- Defining milestones, objectives, and KPIs for the inventory system implementation project.

3.

Engineer inventory software and run QA

At ScienceSoft, this stage includes:

- Delivering the back end of the inventory solution that will consolidate and process inventory data uploaded by users and generated by inventory tracking devices and trigger actions based on this data to automate inventory operations.

- Delivering user-facing web and mobile applications.

- (Optionally) Implementing a demand forecasting module driven by machine learning to optimize inventory management processes.

- Running quality assurance procedures to validate inventory software quality and fix bugs prior to production.

In some cases, upgrading a company’s existing inventory management solution may be a more cost-effective way to get a modern inventory system. We always analyze economic feasibility of inventory software revamp vs. development to decide on the best option and help our clients optimize investments.

4.

Integrate the software with other systems

At this stage, ScienceSoft’s team finalizes integration patterns and procedures defined at the inventory system’s design stage. We implement and test integrations with other business-critical systems and business intelligence (BI) solutions for inventory reporting and visualization of inventory-related data.

5.

Migrate inventory data

Prior to solution launch, ScienceSoft assists in data migration from currently used inventory software or spreadsheets. For this, we take the following steps:

- Developing a migration scenario, scripts for migration automation, data mappings.

- Extracting inventory data from a legacy inventory system or spreadsheets and validating its quality, identifying and solving issues (e.g., lost or corrupted data).

- Loading the data into a dedicated inventory database and running data verification procedures to ensure data accuracy and consistency.

6.

Deploy the inventory system

The deployment of an inventory system with ScienceSoft usually covers the following stages:

Stage 1. Configuring software infrastructure, backup and disaster recovery procedures. Implementing robust security mechanisms: authorization controls for APIs, DDoS protection algorithms, firewalls, IDSs / IPSs, and more. Installing and tuning hardware if required (e.g., barcode printers and readers, RFID tags and readers, computer vision cameras, etc.). Deploying the solution to one of the targeted facilities (warehouse/distribution center) for a pilot run. Duration: 2 weeks for hardware-supported systems.

Stage 2. Monitoring the system’s functioning in real-life conditions. Handling possible change requests and issues (e.g., barcode/RFID-related). Duration of pilot operation: 1-2 months.

Stage 3. Rolling out the final version of the solution to all the targeted facilities. Duration: ~ 2 months for deploying RFID/barcode-based systems (depending on the number of facilities and their layout complexity, the duration can be longer).

7.

Conduct user training

To help employees involved in inventory-related operations quickly learn how to use the solution for their daily operations, ScienceSoft takes the following steps:

- Devising the plan on incorporating the new inventory system into employees’ (inventory and purchasing specialists, warehouse workers) workflows.

- Creating software and hardware administrator guides and user tutorials.

- Conducting workshops for involved user groups (e.g., training warehouse staff to label inventory items for the new system).

8.

Ensure after-launch support

ScienceSoft offers a range of after-launch services to ensure smooth performance of the inventory system in the long run. The services include:

- Providing continuous user support.

- Running planned system updates and extending functionality based on evolving business needs and user feedback, e.g., more types of inventory reports enabled, improved UI.

- For barcode/RFID/computer-vision-supported systems: fixing hardware defects and maintaining hardware (in cooperation with a hardware vendor).

See How It Works in Real Life

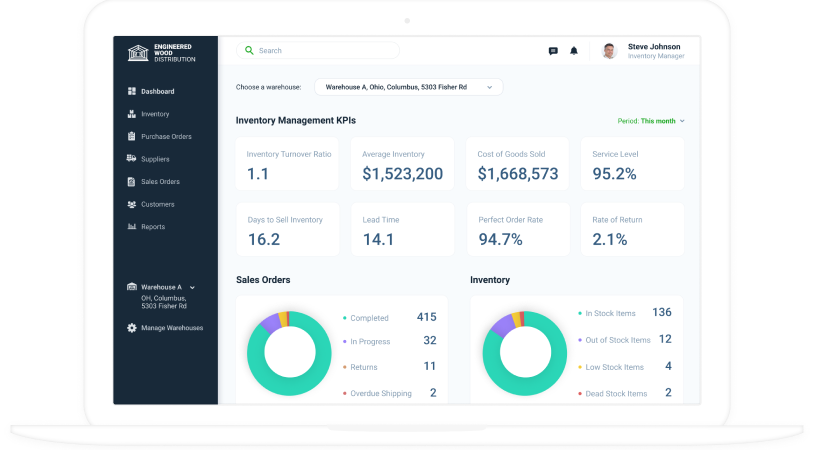

Inventory Management Software Demo

A sample application for the inventory team shows how its key features, like demand-driven inventory planning, multi-location inventory monitoring and automated inventory reporting, improve operations efficiency.

Consider Professional Services for Inventory Software Development

In software engineering since 1989, ScienceSoft helps companies design and build effective inventory systems that help optimize inventory operations and avoid stock-outs and overstocking. We ensure a predictable development process and guarantee that project goals are met within the intended budget and timelines.

Why Engineer Your Inventory System with ScienceSoft

- Since 2012 in supply chain management software development.

- Since 1989 in data science and AI to introduce advanced inventory analytics.

- Since 2011 in IoT to deliver RFID-based inventory tracking capabilities.

- Quick project start (1–2 weeks) and frequent releases (every 2–3 weeks).

- Well-established Agile and DevOps practices.

- Quality-first approach based on a mature ISO 9001-certified quality management system.

- Robust security management supported by an ISO 27001 certificate.

Our awards, certifications, and partnerships

Typical Roles in ScienceSoft's Inventory Software Development Projects

Project manager

Plans the inventory project (goals, timeline, budget), prioritizes the scope of work, monitors its execution, coordinates the project team’s work, reports to the customer.

Business analyst

Investigates and describes functional and non-functional requirements, technical limitations, and needed integrations for the inventory solution.

Solution architect

Designs the architecture of the solution and integration points between its components and other systems (ERP, CRM, accounting system, etc.).

UX designer + UI designer

Conduct user research, design user flows, build prototypes, and gather feedback from users to improve system usability.

Software engineers

Develop the front end and the back end of inventory software, integrate it with other systems.

QA engineer

Designs and implements a test strategy, test plan, and test cases to validate the quality of the inventory system.

NB! Depending on the project specifics, ScienceSoft can involve additional talents, for example, hardware engineers to configure and manage the deployment of an inventory counting (e.g., barcode, RFID) system or data scientists to create advanced inventory analytics models.

Sourcing Models for Creating an Inventory System

ScienceSoft’s Tech Stack for Engineering an Inventory System

To ensure high quality, efficiency, and long-term value of inventory solutions, ScienceSoft usually relies on the following technologies:

Low-code development

Costs of Inventory System Development

Major factors impacting the cost of inventory software projects are:

- The type of an inventory system: software only or a software-hardware system.

- The number and complexity of inventory software features.

- The number of user roles and complexity of a user permission system.

- Uniqueness and complexity of UX/UI design.

- Complexity of data migration procedures, if relevant.

- The scope and complexity of integrations with the required systems.

- Availability, performance, security, latent capacity, and scalability requirements.

- The chosen sourcing model and team composition.

Based on ScienceSoft's experience, the cost to develop an inventory management system may vary from $90,000 to $400,000+.

$90,000–$250,000

An inventory solution of average complexity.

$250,000–$400,000+

A large-scale inventory system integrated with hardware and providing advanced analytics.

About ScienceSoft

ScienceSoft is a global inventory management software development company headquartered in McKinney, Texas. We help businesses start an inventory system that automates even the most complex inventory operations and helps avoid stock-outs and overstockng. Being an ISO 9001- and ISO 27001-certified company, we rely on a mature quality management system and guarantee cooperation with us does not pose any risks to our clients' data security.