Custom Operations Management Software

360-Degree Overview

Operations management tools allow efficiently managing all operational aspects within a single system instead of 3–5 separate applications that require complex integrations.

Since 1989, ScienceSoft has been developing effective operations management software tailored to specific business needs.

The Essence of Operations Management Software

Operations management software (OMS) helps plan, monitor, and coordinate production and service operations, digitalize daily employee workflows, identify and mitigate operational process bottlenecks. Market-available OMS platforms offer a broad range of capabilities for service planning, project management, document management, and project and service analytics. Custom OMS systems are a more feasible option for large-scale or highly specialized business processes that require a large share of tailored software features or need compliance with niche regulations.

Choose the OMS Type You’re Interested In

Software for service operations

For service- and project-centric companies that need to optimize service-related activities and improve management of human resources, projects, service requests, supply chain, T&E, service-related documents.

Software for production operations

For manufacturing-centric enterprises that need to optimize production activities and improve management of inventory, warehouses, workforce, machinery and equipment maintenance, purchase and sales orders.

Factors that Drive ROI of an Operations Management System

In OMS projects, ScienceSoft always seeks to cover the following important factors that may bring additional value for the customer across operations management processes:

End-to-end workflow automation

To improve the productivity of the employees involved in business operations, speed up operational processes, reduce labor costs, and eliminate human errors.

Comprehensive data analytics

To ensure accurate, data-driven operations planning and get intelligent recommendations on optimal resource utilization and operational risk prevention.

Focus on security

To protect the OMS and sensitive data it stores by employing multi-factor authentication, role-based access control, data encryption, AI-powered fraud detection, and other advanced cybersecurity tools.

Mobile access

To enable the operations teams to control the status of production/service operations on the go, streamline the reporting on operations progress and escalation of operational process issues

OMS Implementation Costs and Financial Outcomes

The cost of OMS implementation varies greatly depending on:

- Functionality scope (the number of functionality modules, implementation of AI features, RFID technology, etc.).

- Complexity of data migration procedures (the volume of data that needs to be migrated from the spreadsheets and/or software currently used for operations management).

- Complexity and the number of integrations (with ERP, CRM, PLM, etc.).

Developing custom operations management software of average complexity may cost from $200,000 to $400,000, with an expected payback period starting from 3 months.

An operations management system is an effective way to optimize gross margin and resource utilization.

Custom vs. Off-the-Shelf OMS: Detailed Comparison

|

|

Ready-made OMS |

Custom OMS |

|---|---|---|

|

TCO components

|

Initial setup costs + customization and integration costs + licensing fees that scale with the number of OMS users. |

Upfront investments + the cost of after-launch support and the evolution of the OMS. |

|

Functionality

|

Defined by an OMS product vendor. Additional features are restricted to third-party plugins and extensions. |

Defined by customers and fully tailored to their needs. New features can be introduced on demand. |

|

Customization

|

Limited capabilities. |

Unlimited capabilities. |

|

Integration

|

API-enabled integration with popular software products. Integration with custom solutions and legacy systems may be complex or impossible. |

Seamless connection to all required business systems, including legacy software. |

|

User adoption

|

May be hampered due to complicated, inconvenient UX and UI. |

High due to convenient UX and intuitive UI tailored to various user roles. |

|

Scalability and flexibility

|

Restricted to the vendor’s platform capabilities. |

Non-restricted. |

|

Security

|

Fully depends on the vendor’s cybersecurity practices and cannot be controlled by the customer. |

Minimized security risks due to custom code design and the ability to add advanced security features. |

|

Regulatory compliance

|

Typically limited to compliance with global data security standards. |

Compliance with all the required global, regional, and industry-specific regulations. |

|

Maintenance and support

|

Performed by an OMS product vendor. |

Provided by an in-house team or an outsourced dedicated vendor. |

Since OMS solutions usually contain a lot of complex features, it’s crucial to get a clear idea on the expected financial impact of each function and focus on the modules that offer a high and prompt payoff. Also, I recommend employing an iterative approach to OMS development to introduce the fundamental functionality first and speed up payback.

Benefits of Service Operations Management Software

|

Optimized utilization of resources, including human resources, assets, and inventory. |

Reduction in time to process service requests and requests for project changes. |

Streamlined resource assignment to service requests and new projects. |

|

Full visibility into the progress of service operations. |

Minimized risks of late and over-budget projects. |

Improved customer service in terms of quality, speed, and flexibility. |

Key Features of Service Operations Management Software

Service operations management solutions may cater for businesses with both one-time projects and continuous service operations. They help streamline daily workflows for multiple user groups – operations and resource managers, project managers, service delivery teams, and others. Below, ScienceSoft shares a sample feature set of service operations management software.

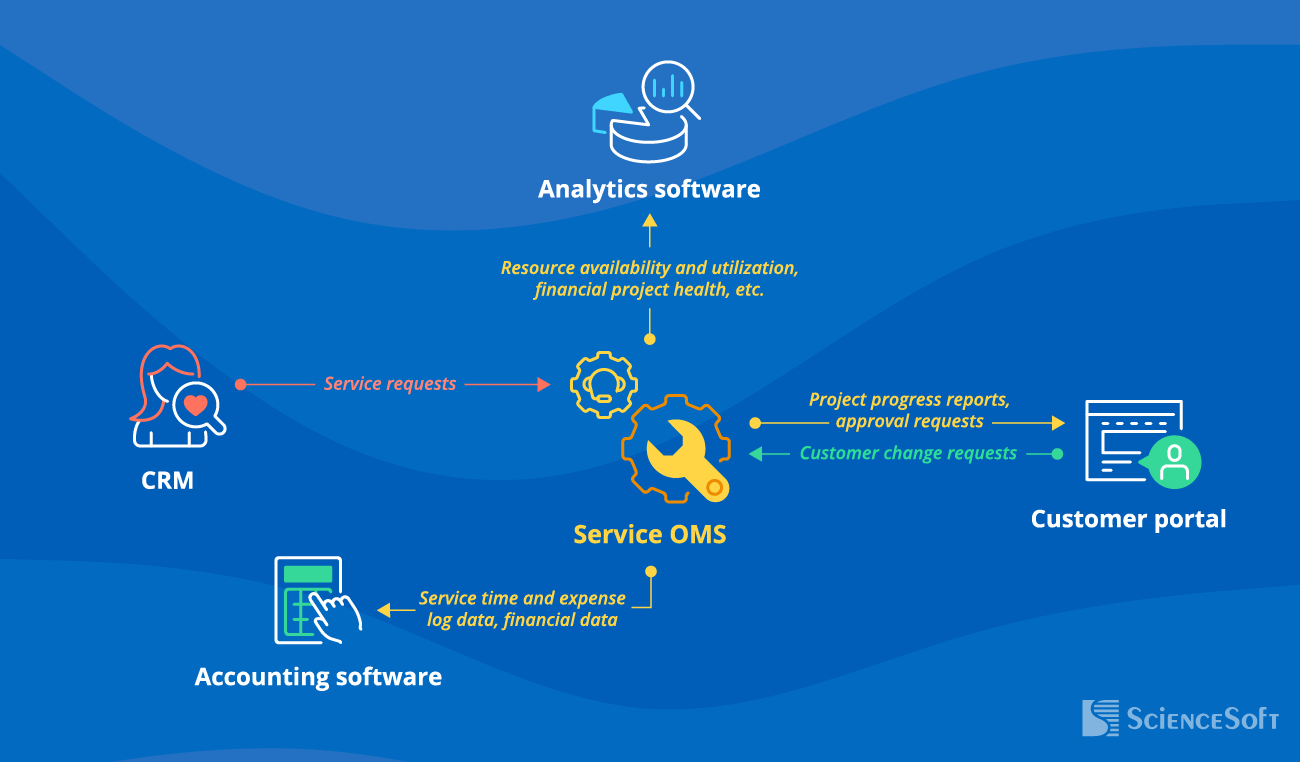

Important Integrations for Service Operations Management Software

To streamline planning, control and analysis of service operations, ScienceSoft recommends that service OMS should be integrated with the following back-office systems:

- OMS + analytics software: to reveal trends in resource availability and utilization, financial project health, etc. and optimize operations planning.

-

OMS + customer relationship management (CRM) software: for fast service request scheduling and assignment to employees; for streamlined creation of a project/task.

-

OMS + a customer portal: to speed up timesheet and expense approvals and keep customers up to date on the project progress; to timely initiate changes in a project.

-

OMS + accounting software: for streamlined customer billing, employee compensation and payroll management; for accurate revenue recording and recognition.

Benefits of Production Operations Management Software

|

Reduced operational costs including labor costs, inventory costs, and asset maintenance costs. |

Enhanced productivity of employees involved in production operations and facilitated cross-team collaboration. |

Faster operational workflows across all production-related processes. |

|

Guaranteed regulatory compliance of production outputs. |

Full visibility into the status of production operations. |

Minimized risks of production operations disruption. |

Key Features of Production Operations Management Software

Having in-depth experience in building production operations management tools, ScienceSoft shares a sample feature set that forms the solution's core. However, each real-life use case for such software is unique, so functionality should be elaborated on and tailored to the business specifics accordingly.

Would you like to improve your production operations?

ScienceSoft will analyze your business needs and implement tailored operations management software to optimize capacity utilization and operations costs.

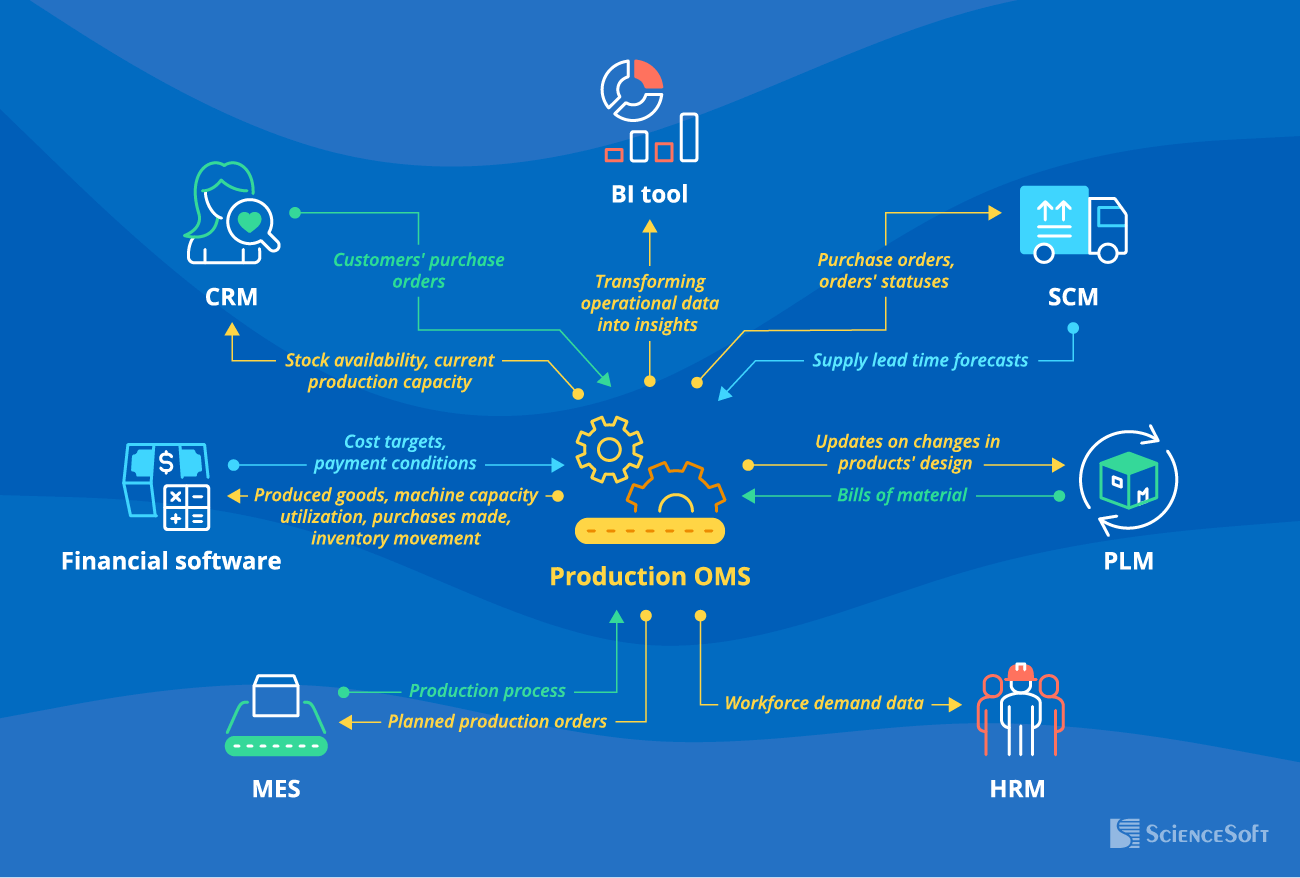

Important Integrations for Production OMS

ScienceSoft recommends integrating production OMS with relevant corporate systems to maximize visibility of production operations, speed up their planning and coordination and improve productivity of involved employees. Essential integrations include:

- OMS + business intelligence (BI) tool: to reveal dependencies and trends that influence operational efficiency, and accurately plan the operations strategy.

-

OMS + supply chain management (SCM) software: for accurate production planning, streamlined purchase order assignment to suppliers and order status monitoring.

-

OMS + customer relationship management (CRM) software: to streamline sales order creation and keep CRM specialists up to date on stock availability and current production capacity (e.g., in case of the make-to-order production strategy).

-

OMS + financial software: for accurate asset and inventory accounting, facilitated compensation and payroll management, streamlined cost control.

-

OMS + product lifecycle management (PLM) software: to automatically attach bills of material (BOMs) to scheduled production orders and ensure prompt updates on the changes in product design.

-

OMS + manufacturing execution system (MES): for streamlined production planning and real-time monitoring of the production process.

-

OMS + human resources management (HRM) software: to assign the proper workforce to different tasks.

How to Develop Operations Management Software

Typically, the process of operations management software development goes through eight standard stages common to any software project. However, we can recommend specific practices to successfully deliver projects focused on operations management.

1.

Planning stage

- We always take time during the discovery stage to explore the target processes, pinpoint time-consuming and error-prone tasks, establish close collaboration with all project stakeholders to envision an ideal process. Only when the process is fully transparent to us, we start consolidating and structuring the requirements.

- In such large-scale software as OMS, thorough requirements engineering also helps scope the project accurately and get a realistic cost estimate from the start. We recommend being particularly meticulous with risks at this step and envision technology, operational, business, and external risk factors that may disrupt the project down the road.

- We enhance the solution with a mobile app to enable remote management of operations when employees are away from the desk (e.g., on the production floor).

- Conflicting interests among stakeholders (e.g., process managers and frontline workers) are common. For instance, a manager may prioritize full automation for efficiency, while a worker may argue that certain tasks require human judgment. Our business analysts acknowledge these conflicts and employ resolution techniques (e.g., decision matrices) before the development starts.

2.

Development stage

- In our practice, iterative development has proved to be effective for such software as OMS. It provides flexibility to work with changing requirements and incorporate feedback from the project stakeholders into each iteration. You can ship the first workable MVP in 4–6 months and continuously evolve it to have your team adapt to the new routine gradually.

- Even if you plan and execute short iterations, it’s important to have a controlled process for change management to assess the feasibility and value of proposed changes to the initial software specification and prevent scope creep.

- We always ensure that the required functionality is wrapped in an intuitive interface. Users tend to abandon features they find confusing.

3.

After-launch stage

- The introduction of new software can be stressful for employees. It's important to facilitate their learning and adaptation by providing user training and guiding employees step by step through the new operational management processes.

FAQs about Software for Operations Management, Answered

What are the major business benefits of operations management applications?

With a robust OMS, you can expect improved employee productivity, faster workflows, optimized asset utilization, and full visibility of business operations. It gives an opportunity to reduce operational costs, minimize the risk of operational disruptions, and drive higher revenue.

Can you develop an operations management platform with advanced features?

Having decades of experience in cloud, AI/ML, big data, IoT, AR, VR, and blockchain, we help our clients design and implement OMS functionality powered with the best-fitting advanced techs to improve the speed, efficiency, and security of service and production operations.

What are the timelines of operations management software development?

Building a custom OMS may take 7–13+ months, depending on the solution complexity and the scope of integrations. We can provide an MVP of operations management software in 3+ months and consistently grow it to a fully-featured system with major releases every 2–4 weeks. We guarantee a quick project start (1–2 weeks) and apply our established Agile and DevOps practices to ensure prompt and smooth OMS implementation.

Operations Management Software Implementation with ScienceSoft

With 36 years of experience in custom software development for 30+ industries, ScienceSoft knows how to design and implement functionally rich and high-performing operations software for streamlined workflows of any complexity.

What our Clients say

We relied on ScienceSoft’s software development competence to reinforce our in-house team working on the evolution of our operations management system. Owing to ScienceSoft’s expertise in agile development, we got biweekly feature releases and were able to complete the design and implementation of the required functionality in less than 4 months.

We particularly appreciate ScienceSoft’s flexible, client-oriented approach to cooperation and pricing, which helped us get the required scope of quality services on time and on budget.

Daniel Tacker, IT System Analyst, Cyber Graphics

About ScienceSoft

ScienceSoft is a global IT consulting and software development company headquartered in McKinney, Texas. Since 1989, we have been creating custom operations management software to help our clients achieve more productive and cost-effective operations. Motivated by shared success, our team of 750+ professionals is ready to deliver an OMS that will fully meet your needs. Visit our custom software development page for more information on our approach.