AI-Powered Film Processing Automation Software for Dwayne’s Photo

Summary

ScienceSoft assisted Dwayne's Photo, a prominent photographic film processor with 60 years of history in the United States, in automating manual photographic film processing. In just six months, our team of an IT consultant, two C++ developers, a data scientist, and a project manager delivered an effective solution based on AI.

About Dwayne's Photo

Established in 1956, Dwayne's Photo is one of the leading photographic film processors in the United States. Based in Parsons, KS, the team of 60 employees receives and processes films from all over the world. They specialize in vintage films: 35mm film, B&W film, and slide films. In 2010, Dwayne's Photo gained international fame: it became the last lab to process Kodachrome, Kodak's iconic film. This fact caught the attention of Netflix, and the company was featured in the movie Kodachrome.

Dwayne's Photo’s goal was to streamline photofinishing. The vast majority of the film the company processes are film rolls in traditional metal canisters. The team combines dozens of 1.5-meter-long rolls of film into a master reel about 120 meters long. This master reel is then taken to the scanner to digitize each frame.

Previously, Dwayne's Photo turned to a third-party IT vendor and got several software prototypes for automating different tasks within the photofinishing process, but the team wasn't completely satisfied with their quality. So, Dwayne's Photo sought an experienced software developer to refine the prototypes and turn them into adequate software.

Automating Film Processing with AI

Trusting ScienceSoft's expertise in C++ programming and data science, Dwayne's Photo turned to us to rework the prototypes into a full-scale film processing automation solution.

ScienceSoft provided a team of an IT consultant, two C++ developers, a data scientist, and a project manager to handle the end-to-end development of the solution.

Software planning

As Dwayne's Photo already had a detailed description of its needs and wants, our IT consultant needed just a week to scope the project, detailing the goals, deadlines and project deliverable we would be working towards.

Creating custom AI algorithms for image stitching

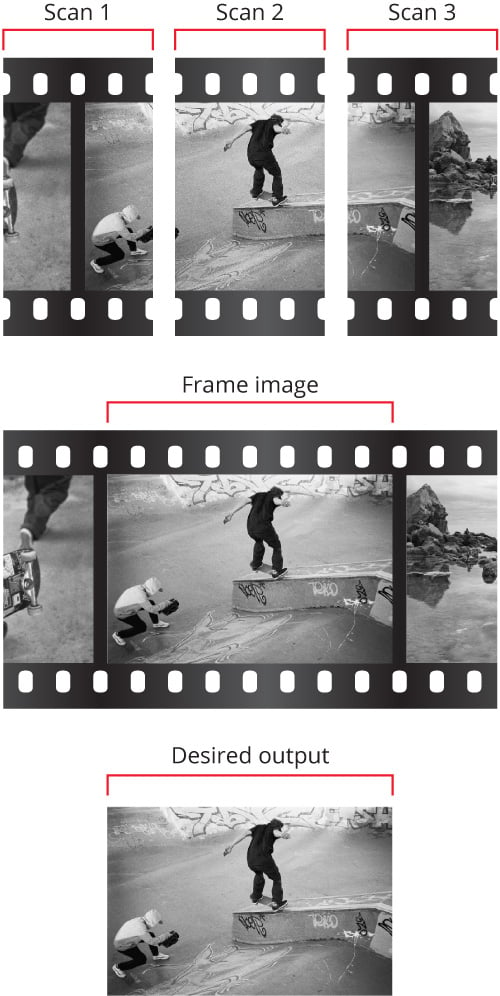

One of the project's key challenges was that the film scanner used by Dwayne's Photo doesn’t capture the full film frame. Rather, it takes several smaller snapshots in the CRI format that need to be stitched together to complete the image (see the illustration below). With a prototype developed by the previous IT vendor, Dwayne's Photo achieved only 60–70% accuracy in stitching, which was insufficient. ScienceSoft's data scientist created a new custom stitching algorithm based on film perforations, axial alignment of images, image overlay techniques, and other factors that helped improve stitching quality. The new algorithm demonstrated >95% accuracy.

Delivering the full-featured solution for automated film processing

ScienceSoft's team refined the prototypes from the previous vendor and integrated them into one smooth automated workflow. The new desktop application works the following way:

- Matching images with orders. To identify different rolls of film on the combined master reel, a barcode reader is used. Mounted on the scanner, the barcode reader captures the barcode identifier with the order ID placed on the splice tape between different rolls in a master reel. The application sends commands to the barcode reader to begin capturing when the scanner is started, record the captured values (order IDs), timestamp them to milliseconds, and stop when the scanner stops.

- Sorting raw CRI files captured by the scanner into dedicated folders named after Order ID.

- Converting CRI files into TIFF or JPG files.

- Stitching several fragments into a complete image using custom AI algorithms.

- Sending ready files to a new directory containing only complete images.

As the requirements were well-defined and fixed, and there was little to no room for changes or iterations during the development process, ScienceSoft's team followed the Waterfall approach. It took six months to scope the project, create custom AI algorithms, and deliver a full-scale solution for film processing automation.

Derek Carter, CEO at Dwayne's Photo, says:

Right from the start, your team showed professionalism and expertise that immediately put us at ease. We appreciate that you examined our needs with great diligence and went above and beyond to develop a solution that fully meets our high demands for image quality. We're sure the new app will help us boost our productivity and help us cater to more clients. Special credit to the data scientist: the performance of the new image stitching algorithm is amazing.

Key Outcomes

- Fully automated film processing, which is faster, less costly, and less error-prone compared to the manual process.

- 95% accuracy of the image stitching algorithm.

Technologies

C++