Augmented Reality (AR) for Maintenance, Repair, and Overhaul

Architecture, Success Stories, Challenges, and Costs

Since 2006, ScienceSoft has been providing augmented reality development services and can help you enhance your repair and maintenance processes with AR.

AR for maintenance and repair helps speed up MRO activities by 15–30% and improve work quality by 90%, driving a significant reduction in MRO costs.

The Market of Augmented Reality for MRO

In 2024, industrial maintenance is expected to receive the largest investment among all commercial use cases for AR – 4.1 billion dollars.

The main factors driving the popularity of AR software for maintenance, repair, and overhaul are the solution’s ability to enhance technicians’ productivity, improve the accuracy and safety of MRO operations, and ensure MRO compliance with industry-specific standards.

Industries in Acute Demand of AR MRO

Aerospace

Automotive

Manufacturing

Oil and Gas

Utilities

Use Cases of AR Software for MRO

Preventive and corrective maintenance

Guiding tips, videos, and visual references aimed to aid in the maintenance are dynamically displayed right in the field of view of the technician, who is performing maintenance and repairs in AR glasses or with the help of a smartphone/tablet.

AR benefits: Reduces maintenance time while ensuring high effectivity; supports on-the-job training.

Equipment/Machinery surveys and audits

Step-by-step augmented reality-assisted checks and audits; the real-world view is enhanced with condition status comments (e.g: damaged, improperly installed, etc.) generated with the help of image processing algorithms.

AR benefits: Accelerates system status checks and guarantees completion of all required audit steps.

Benchmarking and performance data analysis

Comprehensive analysis of equipment and/or industrial machinery performance based on both live performance parameters, received from the equipment/machinery, and benchmark data displayed in the field of view of the technician.

AR benefits: Ensures performance compliance with industry-specific standards.

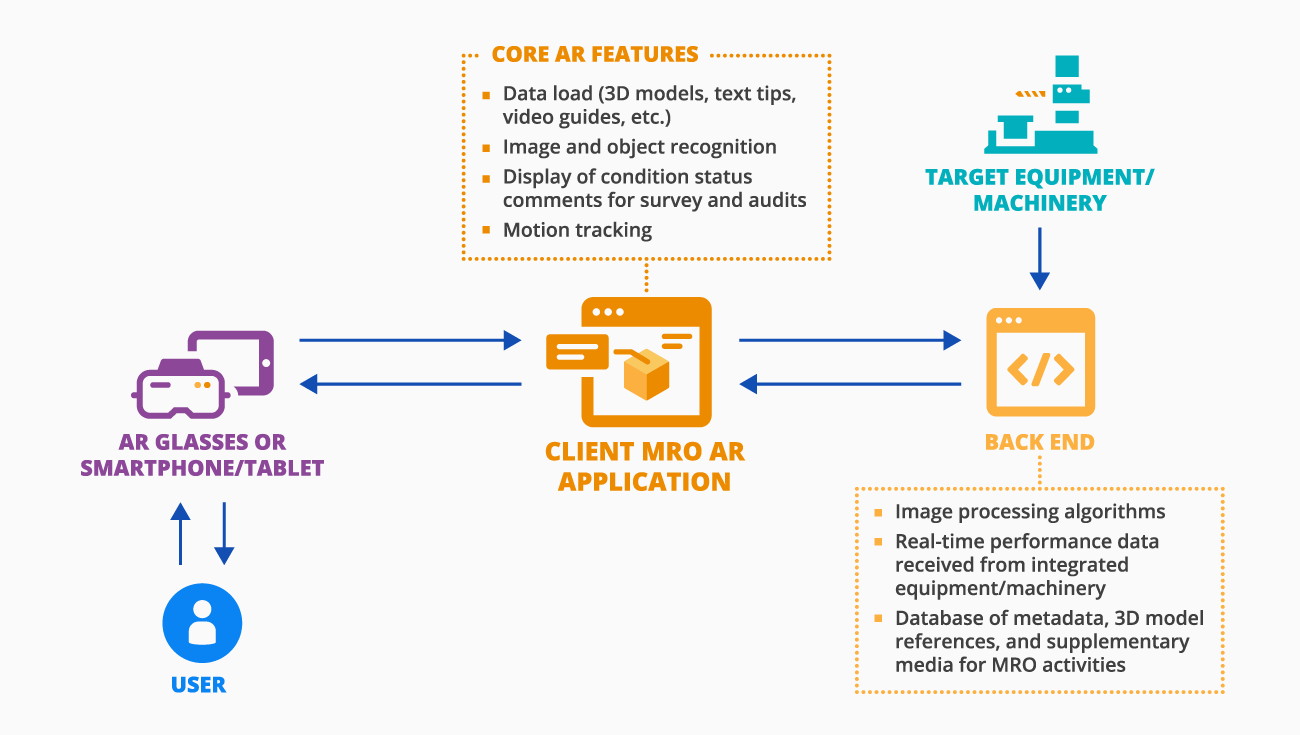

A Sample Architecture of an Augmented Reality Solution for MRO

The two main parts of AR software for maintenance, repair, and overhaul are a client app and the back end. To enable stable and fast performance of the client app on a device (AR glasses, a tablet, a smartphone), all key computer vision algorithms and specific reference data (text tips, 3D models, media) for MRO activities are usually stored on the back end. The back end loads the reference data and processed data captured by AR glasses, a smartphone or a tablet to the client app on demand. The back end can also be integrated with the target equipment/machinery in order to receive performance data and share it with the client app (see Benchmarking use case).

Key Features of Augmented Reality Apps for MRO

On-demand load of metadata, performance data, 3D models, and media

A client app’s request to the back end and a load of relevant MRO tips, equipment/machinery performance data, 3D model references, and voiceover guides or instructing videos.

Image and object recognition

Computer vision-driven recognition of QR codes/pictograms or certain objects (e.g., an engine, turbine) in the camera feed.

Visual inspection and assessment

Detection of recognized objects’ condition status powered by trained image processing algorithms (see Challenge 1 below); detected status comments are displayed as an overlay on the AR device screen

Motion tracking

Automatic adjustment (scaling, angle view, location, etc.) of AR content depending on a technician’s or device movements.

Success Stories of AR in Maintenance, Repair, and Overhaul

|

|

Bosch uses an AR application in its Bosch Car Service workshops. The AR app features navigation arrows indicating locations of the automobile components that aren’t easily visible and provides on-screen instructions to auto technicians about necessary actions to take or tools to use. The company reports that their auto technicians now spend 15% less time on each step of MRO activities compared to when they worked without AR. |

|

|

Boeing uses AR for the assembly of the electrical wiring in their aircraft. Technicians, who used to rely on traditional paper manuals with instructions, now use Google Glass to stream instructions directly in their field of view with voice commands. The innovative approach has reduced error rates to zero and accelerated the wire assembly activities by 25%. |

Challenges of Augmented Reality for MRO: Solved by ScienceSoft

|

|

Visual detection of equipment/machine parts’ condition status requires highly effective image processing algorithms to be reliable. Solution: ScienceSoft’s experience has shown that comprehensive machine learning ensures the high accuracy of computer vision algorithms. We advise training image processing algorithms on datasets containing hundreds of thousands of industry-specific images with detailed descriptions, which makes the algorithms learn to associate specific visual characteristics with respective status conditions and recognize them in the real environment. |

|

|

The AR app should conveniently augment the technician’s field of view with all the necessary information while not overwhelming it. Solution: Our practice has proved that advanced UX and UI design is needed for a shrewd use of the available space on the AR glasses lenses or the screen of an AR-compatible device. To ensure intuitive navigation in AR software, we also run multi-step user testing. |

Implementation Costs

The cost of AR software for maintenance, repair and overhaul ranges between $70,000 and $150,000. The following cost factors are determining.

Key cost factors

- Number and complexity of targeted equipment and/or machinery types.

- Number of possible user scenarios (only benchmarking; audit + preventive maintenance; preventive + corrective maintenance; other combinations.)

- Type of targeted devices (a tablet, a smartphone, AR glasses).

Additional costs

- 3D model development (costs depend on the necessary amount of model detail and type of base material).

- Machine learning training.

- Software integration with equipment/machinery.

Operational costs

- Cloud services (price depends on the provider’s plan and pricing policy).

AR for MRO: Consulting and Development by ScienceSoft

AR software for MRO: consulting

- Finalization of an MRO AR app’s concept.

- Assistance with target device choice.

- MRO AR app architecture design.

- Technology stack definition.

- Planning an integration strategy with third-party software (e.g., ERP) and hardware.

AR software for MRO: development

- MRO AR app conceptualization.

- Device-specific UX and UI design.

- Development and testing of MRO AR app.

- Training of image processing algorithms.

- Design of 3D models.

- Continuous support and evolution.

About ScienceSoft

Founded in 1989 and headquartered in McKinney, TX, ScienceSoft is a global IT consulting and software development vendor. We develop AR software for MRO that can be used for preventive and corrective maintenance, repairs, and audits in automotive, aerospace, manufacturing, oil & gas, and other industries. Being ISO 9001 and ISO 27001 certified, we ensure a professional approach to quality and data security management in all our AR projects.